COMPANY NEWS

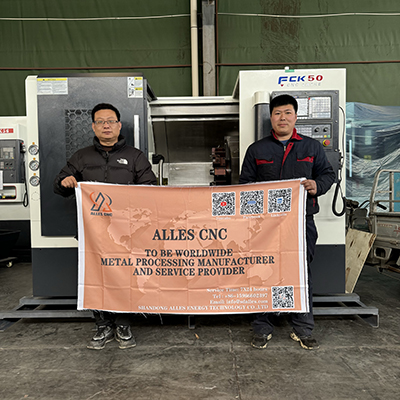

ALFCK50 CNC lathe sent to Russia

The use of CNC lathes can greatly improve processing efficiency and product quality, and provide opportunities for precision machining and continuous processing through computer control. This is one of the key technologies in today's industrial manufacturing. By introducing this technology to the Russian market, it will bring new horizons to local industrial development. CNC lathe ALFCK50 was successfully exported to Russia. It not only demonstrates the technical level and competitiveness of China's manufacturing industry, but also builds a stable and reliable bridge for economic cooperation between the two countries. As an advanced CNC machine tool, ALFCK50 has outstanding advantages in automation, precision and efficiency. The following are the characteristics of the CNC lathe ALFCK50 and its application industries in Russia:

ALFCK50 CNC lathe has the following features:

1. High-precision processing can achieve precise processing of complex parts;

2. Tool replacement is convenient and quick, improving production efficiency;

3. Using advanced CNC technology, it is easy to operate and reduces the difficulty of operation;

4. It has automated processing functions to reduce human intervention and improve production stability;

5. Compact structure and small footprint, suitable for situations where workshop space is limited;

6. Customized configuration can be carried out according to processing needs to meet the processing requirements of different industries.

CNC lathe ALFCK50 is mainly used in the following industries:

1. Aerospace: used for processing aircraft engine parts, aerospace structural parts, etc.

2. Automobile manufacturing: used for processing automobile engines, transmissions, steering gears and other parts.

3. Electronic communications: used for processing metal casings and internal parts of electronic products such as mobile phones, computers, tablets, etc.

4. Mold manufacturing: used to process various mold parts such as plastic molds, die-casting molds, and injection molds.

5. Railway transportation: used for processing railway track parts, train accessories, etc.