PACKING & SHIPPING

Russian ALTCK63-1500 milling machine package

ALTCK63-1500 Turning and Milling CNC Machine Packed and Ready for Shipment to Russia, Boosting Multi-Function Precision Machining

Recently, our ALTCK63-1500 turning-milling compound CNC machine successfully completed rigorous factory inspection and testing, and has been carefully packed for shipment to our customer in Russia. This delivery not only reflects the strong trust Russian clients place in our advanced manufacturing technology, but also marks another successful entry of the ALTCK63-1500 into Russia’s high-end machining market, providing efficient and precise machining solutions for the local manufacturing industry.

Machine Features and Advantages (Examples)

-

Turning & Milling Integration – One Machine, Multiple Functions

The ALTCK63-1500 integrates turning, milling, drilling, and tapping in a single setup. For example, when processing large flanges used in Russian energy equipment, it can complete both outer diameter turning and bolt-hole milling in one clamping, greatly reducing setup time. -

Excellent Long Workpiece Machining Capability

With a 1500mm distance between centers, it is ideal for long shaft machining. For example, in Russian oil drilling equipment, the long drive shaft can be machined in one setup, ensuring coaxiality and precision. -

High Rigidity and Superior Stability

The high-strength cast iron bed with wide guideways ensures vibration resistance. Even when machining hardened steel (such as bearing steel or alloy steel), it maintains surface finish and dimensional accuracy. -

High Efficiency and Labor Savings

Multi-process machining in one setup reduces part handling and re-clamping time. For example, when producing parts for Russian railway bogies, the single-part processing time can be reduced by over 30%. -

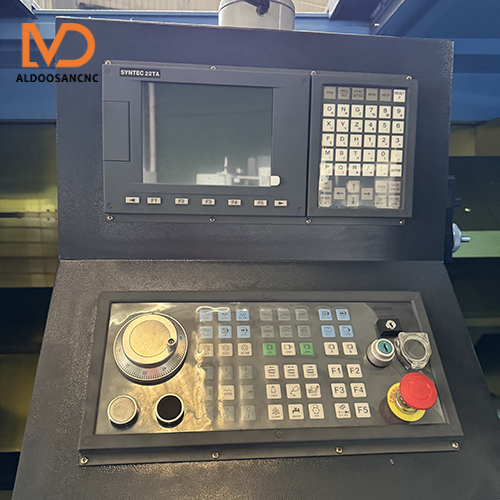

Intelligent Control and Easy Operation

Equipped with a high-performance CNC system and servo drive, it supports complex surface machining and multi-axis linkage. The intuitive interface allows operators, even beginners, to quickly master programming and operation.

Applications in Russia

-

Energy Equipment Manufacturing – Oil & gas drilling tool parts (drill bit joints, long shafts, flanges)

-

Railway & Transportation Equipment – Locomotive bogie components, wheel axles, transmission shafts

-

Heavy Machinery Manufacturing – Large mining machinery parts, slewing bearings for construction machinery

-

Defense & Aerospace – Aircraft landing gear parts, guide shafts, structural rings

-

Shipbuilding – Propeller shafts, rudder stocks, other precision long shafts

The shipment of the ALTCK63-1500 to Russia will help customers improve production efficiency and machining accuracy, especially for complex parts and multi-process machining tasks. We will continue to provide high-performance, reliable CNC machine solutions to customers in Russia and worldwide, supporting high-quality manufacturing development.