PACKING & SHIPPING

ALCK0640 CNC lathe packaging

ALCK0640 CNC Lathe Successfully Packed and Ready for Shipment to Overseas Customer

Recently, our self-developed ALCK0640 CNC lathe successfully passed quality inspection, completed protective packaging, and is now ready for shipment to an overseas customer. With its compact design, high-precision machining capability, and excellent cost-performance ratio, this model is highly recognized in the global market, especially for batch production and efficient machining of small precision parts.

Key Features and Advantages of ALCK0640 CNC Lathe

-

Integrated cast iron bed for excellent rigidity and vibration resistance, ensuring stable machining accuracy over time;

-

High-precision ball screw and linear guideways for smooth operation and high repeatability;

-

Optimized machining diameter and length suitable for a variety of small and precision part processing needs;

-

Compatible with multiple CNC systems (GSK, KND, FANUC, etc.), featuring a user-friendly interface for easy operation;

-

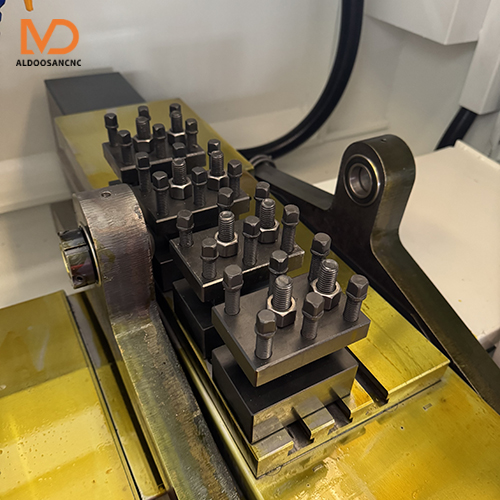

Optional automatic tool turret, tailstock, and other attachments for enhanced multi-process machining capability.

Application Industries

The ALCK0640 CNC lathe is suitable for various metalworking industries, including:

-

Automobile and motorcycle parts machining (bolts, shafts, sleeves, etc.);

-

Precision parts manufacturing for electronics and instruments;

-

Production of hardware tools and small mechanical components;

-

Teaching and training in technical schools and institutes.

This model offers stable machining accuracy and efficiency while requiring minimal floor space and low maintenance costs, making it ideal for small and medium-sized enterprises as well as individual workshops. This shipment not only reflects the customer's trust in our product quality but also demonstrates our growing competitiveness in the global precision machining equipment field. Moving forward, we will continue to provide high-quality CNC machines and comprehensive technical support to help customers achieve intelligent and efficient production.