PACKING & SHIPPING

CNC lathe ALCK6150X1000 packed and shipped to Colombia

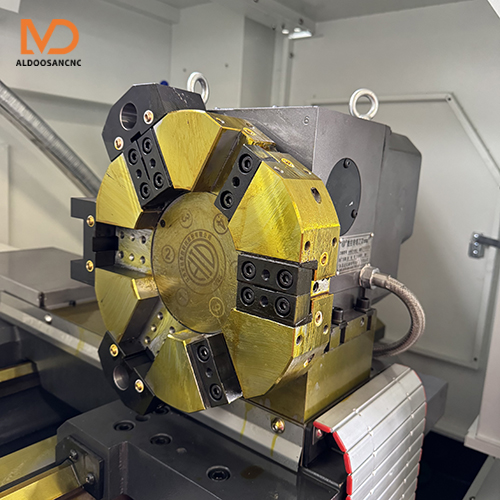

ALCK6150×1000 CNC Lathe Successfully Packed for Shipment to Colombia, Supporting Local Machinery Manufacturing and Metalworking

Recently, our self-developed ALCK6150×1000 CNC lathe successfully completed final factory inspection, was professionally packaged, and is now ready for shipment to our customer in Colombia. With its high rigidity, high precision, and powerful machining capabilities, this machine can fully meet the needs of Colombia’s machinery manufacturing and various metalworking industries, providing efficient and stable production solutions.

Main Features and Advantages of ALCK6150×1000 CNC Lathe

-

High-strength cast iron bed with excellent rigidity and vibration resistance, ensuring long-term machining accuracy;

-

Maximum turning diameter of 500mm and machining length of 1000mm, ideal for efficient turning of medium and large-sized parts;

-

Precision spindle system combined with high-accuracy ball screw transmission for superior machining accuracy and repeatability;

-

Compatible with multiple CNC systems such as GSK, FANUC, and KND, with user-friendly operation;

-

Optional automatic tool turret and tailstock to enhance multi-process machining capability.

Main Application Industries in Colombia

-

Machinery manufacturing: turning shafts, discs, and sleeve-type parts;

-

Energy and mining machinery: manufacturing and repairing mining equipment and power generation components;

-

Transportation equipment manufacturing: producing parts for railways, ships, and construction vehicles;

-

Agricultural machinery: producing and repairing key agricultural equipment parts.

This shipment not only demonstrates the Colombian customer’s strong trust in the quality and performance of our CNC machines, but also marks our further expansion in the South American market. In the future, we will continue to provide high-performance and highly reliable CNC machines along with comprehensive technical support to help customers improve production efficiency and achieve intelligent manufacturing.