PACKING & SHIPPING

ALCK6166X1000 CNC lathes packed and shipped to Paraguay

CK6166×1000 CNC Lathe Packed and Ready for Shipment to Paraguay to Boost Heavy-Duty and High-Precision Machining

Recently, the CK6166×1000 CNC lathe customized for our South American client successfully passed complete debugging and factory inspection. It has now been professionally packed and will soon depart for Paraguay. Renowned for its high rigidity, stability, and strong cutting performance, this model is ideal for efficient and stable turning of medium to large workpieces, helping local manufacturers enhance productivity and machining quality.

Main Features and Advantages

l High-strength integral cast iron bed (widened and thickened) for excellent vibration resistance and structural rigidity, ensuring stable accuracy over long-term use.

l Max swing diameter ≈ 660mm, machining length 1000mm to cover mainstream sizes of shafts, discs, and sleeve parts.

l Precision spindle unit with high torque, low vibration, and compatibility with heavy cutting and fine finishing; universal spindle nose for easy clamping.

l High-precision X/Z axis ball screws with linear/precision guideways for high transmission efficiency and stable repeatability.

l Efficient lubrication and chip removal system to reduce wear and ensure continuous machining reliability.

l Compatible with GSK/FANUC/KND CNC systems for user-friendly operation and program compatibility.

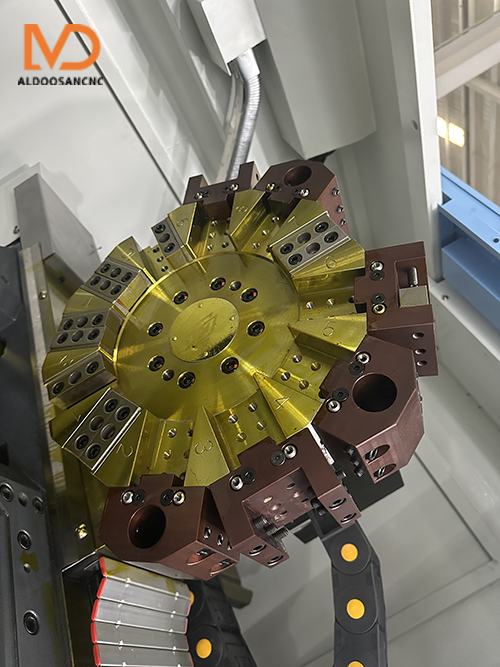

l Optional turret, tailstock, oil-water separator, and through-spindle coolant for multi-process and long shaft machining.

l Full safety protection with enclosed sheet metal and electrical interlocks for clean and safe operation.

Main Applications in Paraguay

1. Agricultural and construction machinery: mass production and maintenance of shafts, gear blanks, bushings, and flanges.

2. Energy equipment (power generation, pumps, valves): medium and fine machining of flanges, pump shafts, and valve bodies.

3. Transportation and logistics equipment: machining of hubs, brake drums, and drive shaft joints.

4. Mining and metallurgical parts: heavy-duty machining of rollers, wear sleeves, couplings, and bearing seats.

5. Repair workshops and small manufacturers: multi-variety, small-batch customization with quick delivery.

This shipment reflects our client’s recognition of our product quality, delivery capability, and after-sales service. We will continue to serve the South American market, offering highly reliable CNC machines and comprehensive process support to help clients in Paraguay and beyond achieve higher efficiency, lower costs, and stable quality in intelligent manufacturing.