PACKING & SHIPPING

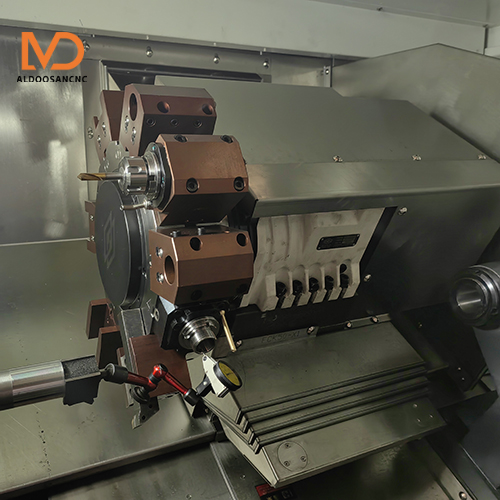

ALFCK50 Slant Bed CNC Lathe Belarus Inspection Machine

ALFCK50 CNC Lathe Successfully Accepted in Belarus

Recently, the ALFCK50 CNC lathe produced by our company successfully passed the acceptance inspection at the customer’s site in Belarus. The client highly praised the machine’s machining accuracy, operational stability, and overall assembly quality, while also recognizing the professionalism of our technical service team. This successful inspection not only demonstrates our company’s strength in CNC equipment manufacturing but also lays a solid foundation for future cooperation.

Main Features of the ALFCK50 CNC Lathe

-

45° Integrated Slant Bed Structure – Strong rigidity, smooth chip removal, ideal for long-term continuous machining.

-

High-precision Roller Linear Guideways – Ensures machining accuracy and machine longevity.

-

High-power Servo Spindle Motor – Delivers high-speed cutting and stable performance.

-

Full Enclosure Design – High safety and a clean working environment.

Advantages of the ALFCK50 CNC Lathe

-

High machining efficiency, suitable for mass production.

-

Excellent stability, reducing downtime and maintenance.

-

User-friendly operation, suitable for operators of various skill levels.

-

Easy maintenance, lowering operational costs.

Application Industries in Peru

The ALFCK50 CNC lathe is widely used in Peru for:

-

Mining machinery parts processing

-

Agricultural machinery manufacturing

-

Automotive and motorcycle parts production

-

Construction machinery and infrastructure equipment manufacturing

This successful acceptance in Belarus not only showcases the superior performance of the ALFCK50 but also provides strong support for its further promotion in the South American market. We will continue to focus on high-quality manufacturing and excellent service, offering reliable CNC machining solutions to customers worldwide.