COMPANY NEWS

How to Choose the Best CNC Lathe for Your Workshop? The Ultimate Guide to 2025

How to Choose a CNC Lathe? Supplier Guide | SHANDONG ALLES ENERGY

Introduction

Choosing the right CNC lathe can be overwhelming. With so many models, configurations, and price points, making the right decision is critical—it directly impacts your production efficiency and product quality.

At SHANDONG ALLES ENERGY TECHNOLOGY CO., LTD, with years of industry expertise, we’ve created this ultimate guide to help you clearly understand how to choose the CNC lathe that best fits your business needs.

Step 1: Define Your Machining Needs

Before comparing models and prices, ask yourself these key questions:

What materials will you machine? (Steel, aluminum, copper, titanium, or plastics?)

What are the typical workpiece sizes and complexity? (Diameter, length, milling or drilling requirements?)

What level of accuracy and surface finish do you need? (Tolerance requirements)

What is your expected production volume? (Small batch with variety or large-scale production?)

Your answers will directly determine the type of CNC lathe you should invest in.

Common Types of CNC Lathes and Applications

Horizontal CNC Lathe – The most versatile option, suitable for the majority of rotating parts.

Vertical CNC Lathe – Best for large and heavy workpieces, using gravity for stable clamping.

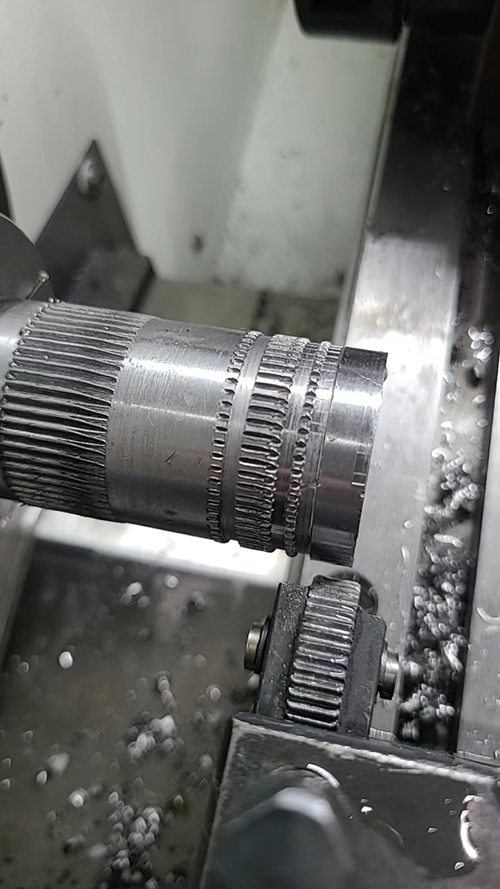

Slant Bed CNC Lathe – Offers higher rigidity, smoother chip removal, and greater accuracy.

CNC Turning-Milling Center – Combines turning and milling in one setup, ideal for complex parts.

Swiss-Type Automatic Lathe – Designed for small, ultra-precise shaft components, widely used in medical and electronics industries.

5 Key Features to Evaluate

Spindle Speed & Power – Determines efficiency and material capability.

Bed & Guideways – Slant beds and linear guideways provide higher rigidity and precision.

Turret Capacity – More tool stations allow complex machining in one setup.

CNC Control System – Fanuc, Siemens, or Mitsubishi. Look for reliability and user-friendly interfaces.

Accuracy & Repeatability – Critical quality indicators that impact your product’s success rate.

Beyond the Machine: Why Supplier Choice Matters

A CNC lathe is not just metal and electronics. Its long-term value depends heavily on the manufacturer behind it:

Quality & Reliability – Strong castings, high-quality ball screws, and guideways ensure durability.

Technical Support & Training – Quick response service reduces downtime.

Spare Parts Availability – Fast delivery of parts keeps your workshop running.

Customization Capability – Tailored solutions for your unique production needs.

Why Global Customers Choose SHANDONG ALLES ENERGY

At SHANDONG ALLES ENERGY, we don’t just sell machines—we provide productivity solutions.

l Full Product Range – From manual lathes to advanced multi-axis turning-milling centers.

l Robust Design – High-quality cast iron and proven engineering for long-lasting performance.

l Direct Pricing – Competitive costs without middlemen.

l Comprehensive After-Sales Service – Installation guidance, operator training, and reliable spare part supply.

Ready to Upgrade Your Workshop?

Looking for a reliable and cost-effective CNC lathe? Our expert team is ready to recommend the most suitable model based on your needs—and provide highly competitive pricing.

[Click here to get a free product catalog and quotation] (link to your contact or catalog page)

Or contact us directly:

WhatsApp: Contact me (Talk to Sales Manager Stella)

Email: cncfactory@allescnc.com

Let’s work together to build a more efficient and profitable workshop.