PRODUCT

ALVMC850 cnc machine center

The workpiece of ALVMC850 machining center can complete the processing of milling, drilling, boring, reaming, tapping and other processes continuously after one clamping. It is suitable for small parts such as plates, discs, shells, molds and other complex Cutting of parts. Widely used in machinery manufacturing, automobile, mold, aerospace and other industries.

ALVMC850 machining center uses a three-axis full-line rail vertical CNC milling center. The high-speed displacement enables this series to obtain production efficiency and benefits. It is the best model choice for communications, auto parts, hardware, and medical equipment. Pursuing high precision and high efficiency, it is the best choice for processing 3C parts and hardware products because of its excellent performance in the breadth and depth of processed products.

Features of ALVMC850 metal processing center:

1. High precision: CNC metal milling machine ALVMC850 adopts high-precision linear guide rail and precision ball screw, which can realize high-precision machining.

2. High efficiency: CNC metal milling machine ALVMC850 adopts high-speed spindle, which can realize high-speed cutting and improve processing efficiency.

3. High reliability: high-quality machine tool materials and advanced manufacturing technology ensure the long-term stability and reliability of the machine tool.

4. High stability: The vertical CNC milling machine ALVMC850 adopts a high-rigidity machine tool structure and optimized machine tool design, which ensures the stability of the machine tool during processing.

ALVMC850 CNC machine tool metal milling application:

1. Parts processing: ALVMC850 CNC machine tool metal milling is widely used in parts processing fields of automobile, aerospace, electronics and other industries. It can efficiently and precisely process various parts with complex shapes, such as gears, threads, apertures, etc., to meet the requirements of industrial manufacturing

2. Mold processing: Mold manufacturing is a part of modern manufacturing industry. ALVMC850 CNC machine metal milling CNC lathe has advantages in the field of mold processing. It can realize multi-angle and multi-axis processing, and improve the precision and efficiency of mold making

3. Steel processing field: ALVMC850 CNC milling machine can be used to process bearings, bushings, journals and other parts to improve production efficiency and product quality. Its excellent performance and reliability make it a key tool in the processing field and promote the development and progress of related industries.

4. In the field of power generation equipment: ALVMC850 CNC milling machine is widely used in the processing of key components of wind power generators, such as horizontal spindles, wind wheels, gearboxes, generators, etc. The processing is difficult and requires high precision. CNC machine tools can better solve complex, precise, small batch and multi-variety parts processing problems.

ALVMC850 metal processing center standard configuration:

1. Spindle unit

2. Supercharged knife cylinder

3. X direction ball screw pair

4. Y direction ball screw pair

5. Z direction ball screw pair

6. Precision nuts

7. XYZ roller guide rail

8.Screw bearing

9. Cooling pump

10. New generation system of automatic lubrication system electrical system

Optional configuration of ALVMC850 metal processing center:

1. Shaft hard rail

2. Two lines and one hard

3. Axis rail

4. Spindle center water outlet

5. Spindle oil cooling

6. Bucket tool magazine

7. Disk magazine

8. FANUC system

9. CNC dividing head

10. CNC rotary table

11. Bridge plate combination turntable

10 CNC five-axis turntable

Video:

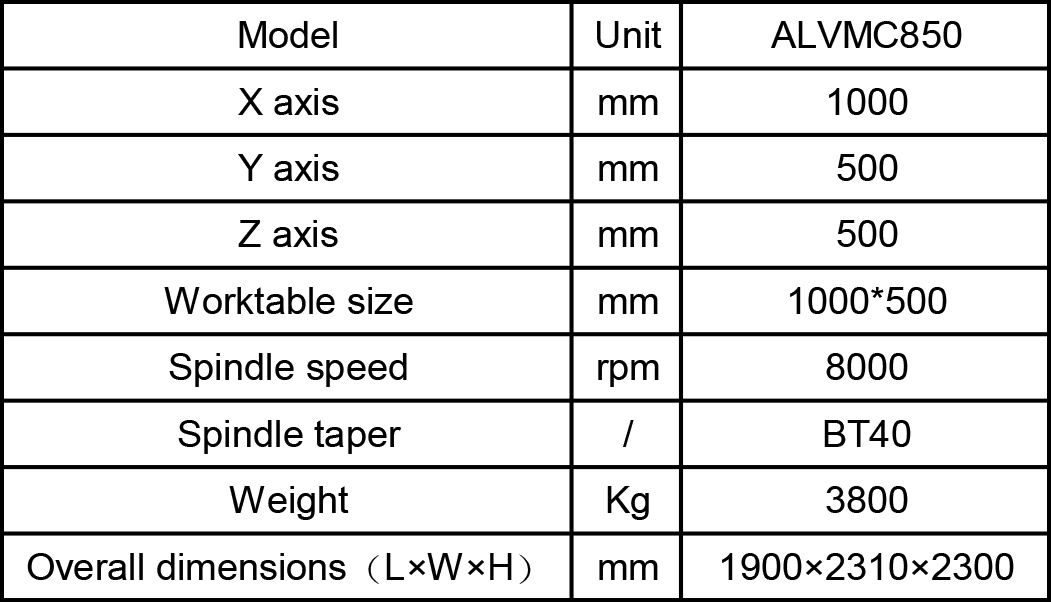

Product parameters: