PRODUCT

ALTCK6340 cnc lathe machine

Inclined bed CNC lathe TCK6340 cnc lathe machine performs batch, high-efficiency, high-precision automatic processing on the conical surface, arc surface, end surface and various metric and inch threads of rotary parts. It adopts a 45-degree high-rigidity integral bed and a high-precision spindle unit. using Taiwan line rails to ensure the high rigidity of the whole machine, the center of the spindle is close to the operator, and it is more convenient to load and unload the workpiece.

TCK6340 slanted bed CNC lathe is a high-speed, high-reliability slanted bed machine bed, bed, bedside box and other main components are cast from high-strength materials to ensure the long-term stability of the machine tool. 45° overall inclined bed structure, the machine tool has high positioning accuracy, smooth chip removal, suitable for high-speed and high-finish machining. Indoor assembly, 72 hours of continuous running-in at constant temperature after assembly, and 72 hours of continuous trial operation after being put on the machine to ensure reliable high-speed and high-precision performance. The factory arrangement method is adopted, with fast tool change speed and high positioning accuracy.

Features of ALTCK6340 cnc lathe machining:

1. High-precision processing: The metal ALTCK6340 CNC lathe has excellent precision and can achieve micron-level processing accuracy, ensuring that the manufactured parts have a high degree of accuracy and quality.

2. Digital control: This CNC lathe adopts advanced digital control technology and has a friendly operating interface. It can easily process complex parts through pre-programming, reducing operator dependence.

3. Versatility: The metal ALTCK6340 is equipped with a variety of cutting tools and accessories, which can handle different types of processing tasks, including turning, drilling, boring, tapping, etc., providing an all-in-one processing solution.

4. Efficient production: The horizontal CNC lathe ALTCK6340 has a high degree of automation, greatly improving work efficiency, reducing labor costs, and shortening the production cycle.

5. Durability and reliability: Designed and manufactured to high standards, with excellent durability and reliability, adaptable to various working environments.

Uses of ALTCK6340 cnc lathe machining:

1. Aerospace industry: Used to manufacture key components such as aircraft parts, missile components, and engine casings to ensure the high precision and reliability of aircraft and spacecraft.

2. Automobile manufacturing industry: Used in the production of automobile parts, such as engine blocks, steering gears, brake discs, etc., to improve the performance and safety of automobiles.

3. Mold manufacturing: In the mold manufacturing industry, ALTCK6340 CNC lathe is used to manufacture molds and mold parts, meeting the production needs of a variety of industrial and consumer products.

4. Electronic manufacturing: In the field of electronic manufacturing, it is used to manufacture precision electronic components, connectors, conductive components, etc. to ensure the performance and quality of electronic products.

5. Medical equipment manufacturing: Used to manufacture high-precision components for medical equipment, including medical imaging equipment, surgical tools, and medical instruments.

6. Ship manufacturing: In the shipbuilding industry, it is used to manufacture hull parts, propellers and propulsion systems to ensure the safety and performance of ships.

7. National defense industry: In the field of national defense, ALTCK6340 CNC lathe is used to manufacture various parts of military equipment, such as tank parts, artillery barrels, etc.

ALTCK6340 cnc lathe machine standard configuration:

1. Servo main motor

2.140 mm spindle unit (3500 rpm)

3. Taiwan Straight Line Railway

4. Ball screw

5. Hydraulic chuck

ALTCK6340 slanted bed CNC lathe optional configuration:

1. Spindle unit

2. Ball screw

3.6/8 station electric turret

4.8/12 station hydraulic turret

5. Hydraulic Chuck

6. Chip conveyor

video:

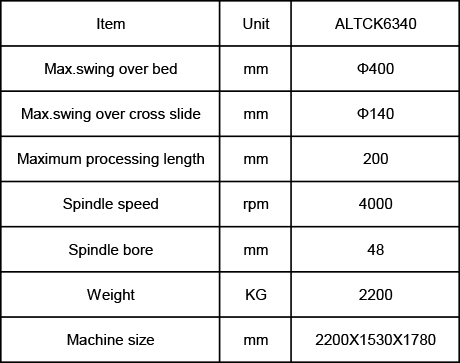

Product parameters: