PRODUCT

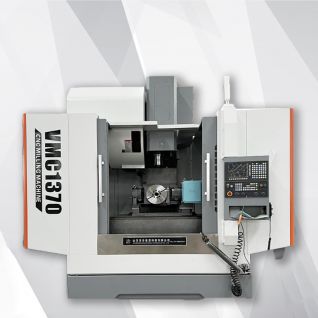

ALVMC1370 cnc machine center

VMC1370 CNC machining center is a fully functional CNC machine tool. The CNC metal milling machine VMC1370 integrates milling, drilling, reaming, boring, tapping and thread cutting, making it capable of a variety of process methods. Compared with ordinary machine tools, machining centers have many significant technical features. When processed on a mold machining center, the process is highly concentrated. Most or even the entire surface of the part can be processed in one clamping, which avoids clamping errors caused by multiple clampings of the workpiece, so the machined surface can be obtained. The mutual position accuracy is high. The entire processing process is automatically controlled by the program and is not affected by human factors of the operator. With the position compensation function of the machine tool, the positioning accuracy and repeated positioning accuracy are high, and the dimensional consistency of the processed parts is good.

VMC1370 CNC machining center is equipped with automatic tool exchange system, fully enclosed protective cover, automatic lubrication system, cooling system, automatic chip removal device, and portable manual operation device. After the part is clamped once, it can complete multi-process processing such as milling, boring, drilling, expanding, reaming, tapping, etc. It has high degree of automation, strong reliability, simple, convenient and pleasant operation, beautiful overall shape, and high degree of mechanical and electrical integration. advantage.

Features of VMC1370 CNC machining center:

1. Rigid structure: VMC milling machine ALVMC1370 adopts a solid vertical structure with excellent rigidity and stability to ensure high-precision processing.

2. High-speed cutting capability: The machining center of the VMC milling machine ALVMC1370 is usually equipped with a high-speed spindle and a rapid feed system, which can achieve high-speed cutting and improve production efficiency.

3. Automation functions: VMC milling machine ALVMC1370 usually has automation functions such as automatic tool switching, automatic workpiece loading and unloading, and CNC operations, which reduces manual intervention and improves production efficiency.

4. Multi-axis control: CNC metal milling machine ALVMC1370 machining center usually has multi-axis control function, which can realize multi-axis processing of complex parts, such as five-axis processing, improving the diversity and accuracy of processing.

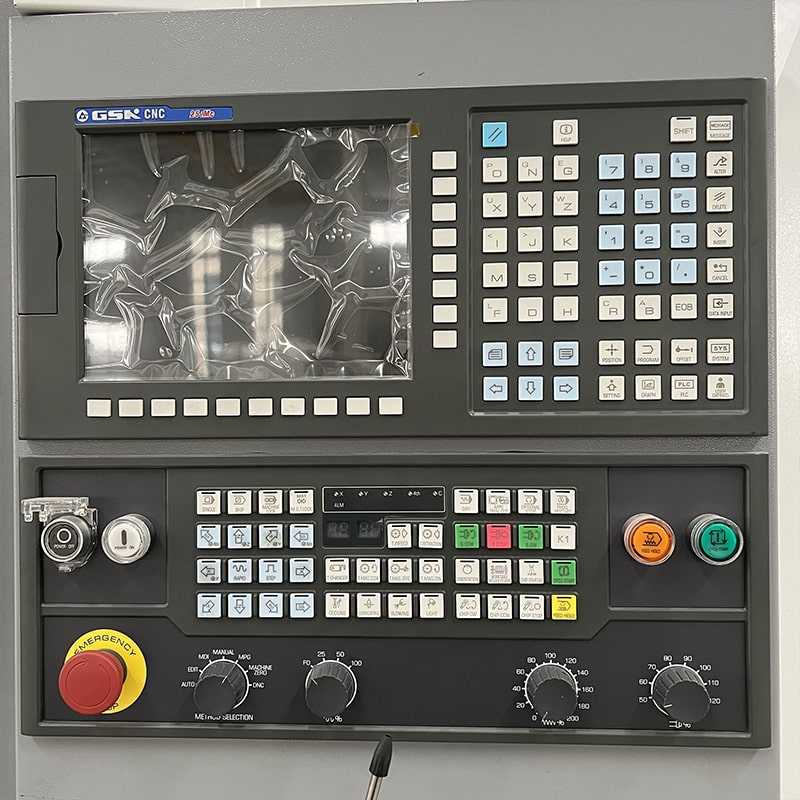

5. CNC system: CNC metal milling machine ALVMC1370 usually adopts an advanced CNC system, which is highly programmable and can perform high-precision and complex processing tasks.

6. Wide application: CNC metal milling machine ALVMC1370 is widely used in aerospace, automobile manufacturing, mold manufacturing, medical equipment manufacturing, electronic equipment manufacturing and other fields. It is especially suitable for industries that require high-precision and high-efficiency processing.

7. Large tool magazine capacity: Mini CNC milling machine metal ALVMC1370 usually has a large-capacity tool magazine, which can accommodate a variety of different types of tools to adapt to different processing needs.

8. High-precision processing: Due to its rigid structure and advanced control system, the mini CNC milling machine metal ALVMC1370 is suitable for the processing of high-precision parts, such as molds, precision parts, etc.

ALVMC1370 CNC machine tool metal milling application:

1. Aerospace: In the aerospace industry, the vertical CNC milling machine ALVMC1370 is used to manufacture aircraft parts, engine parts, aircraft structural parts, etc. Its high-precision and high-efficiency machining capabilities are critical to ensuring aircraft performance.

2. Automobile manufacturing: In the field of automobile manufacturing, the vertical CNC milling machine ALVMC1370 can be used to produce automobile engine parts, chassis parts, body structures, etc. It can achieve high-precision machining of complex parts and improve vehicle quality and performance.

3. Mold manufacturing: The vertical CNC milling machine ALVMC1370 is very important for the mold manufacturing industry and can be used to manufacture injection molds, die-casting molds, stamping molds, etc. High precision and multi-axis control capabilities make it suitable for precision mold manufacturing.

4. Medical device manufacturing: Medical device manufacturing often requires highly precise parts, such as prostheses, surgical tools, etc. Chinese CNC milling machine ALVMC1370 can be used to produce these parts, ensuring their quality and reliability.

5. Electronic equipment manufacturing: Chinese CNC milling machine ALVMC1370 can be used to process parts of electronic equipment, such as circuit boards, radiators, casings, etc. Its high-speed cutting and high precision make it ideal for the electronics manufacturing industry.

6. Energy industry: In the energy field, the Chinese CNC milling machine ALVMC1370 can be used to manufacture components for wind and solar equipment, such as wind turbine parts, solar panel brackets, etc.

7. General machinery manufacturing: In addition to the above industries, the CNC milling machine ALVMC1370 is also suitable for general machinery manufacturing, such as the production of bearings, gears, hydraulic components, etc.

Standard configuration of ALVMC1370 CNC metal processing center:

1. Body material

2. Body structure

3. Table specification (length X width)

4. The maximum load of the workbench

5. X.Y/Z axis coordinate travel

6. The distance from the spindle center line to the front guide rail of the column

7. The distance from the end face of the spindle to the upper plane of the workbench

8. X, Y, Z cutting feed

9. X, Y rapid feed speed

10. Z rapid feed speed

11. Spindle speed range

12. Main shaft structure and function

13. Spindle motor power

14. Repeat positioning accuracy

15. Positioning accuracy

16. CNC system

17. Disc manipulator type (high speed) tool magazine

18. Machine Tool Outline Dimensions (LXWXH)

Optional configuration of ALVMC1370 CNC metal processing center:

1. CNC operating system

2. Spindle center water outlet

3. Spindle oil cooler

4. Spiral chip conveyor

5. Chain chip conveyor

6. Four-axis turntable

Video: