PRODUCT

ALCK6166X1000 cnc lathe machine

ALCK6166X1000 cnc lathe machine CNC lathe is made of cast iron, rolled bamboo bar and sheet, it is a new type of CNC lathe. ALCK6166X1000 series CNC horizontal lathe has the characteristics of high precision, high power, high rigidity, etc. Its main components and structure have been optimized.

ALCK6166X1000 cnc lathe machine is a CNC lathe with high precision, high performance and strong versatility. It is used to process various shaft and disk parts. It can automatically complete the processing of internal and external circular surfaces, conical surfaces, arc surfaces, end surfaces and other rotary surfaces, as well as turning threads. It is suitable for high-volume and high-efficiency processing of various high-precision, complex, medium and small rotary parts in the industries of instrumentation, electronic engineering, medical equipment, aerospace, auto parts, and textiles.

Features of ALCK6166X1000 CNC lathe and milling machine:

1. High-precision processing: ALCK6166X1000 CNC lathe and milling machine adopt advanced CNC technology and high-precision transmission device to achieve high-precision processing of workpieces. Its precise tool control and worktable movement system ensures that excellent processing quality can be maintained even in the processing of tiny parts.

2. High-power spindle: Equipped with high-power spindle, ALCK6166X1000 CNC lathe and milling machine can adapt to the processing needs of various materials. Whether it is metal, plastic or composite materials, processing tasks can be completed quickly and efficiently, improving production efficiency.

3. Flexible and diverse processing capabilities: ALCK6166X1000 CNC lathe metal lathe has a multi-axis linkage control system, which can realize a variety of processing operations, including turning, drilling, tapping, etc. This flexible versatility makes this CNC lathe suitable for processing various complex workpieces, providing more production options.

4. User-friendly operation interface: ALCK6166X1000 CNC lathe metal lathe equipment is equipped with an intuitive and easy-to-use CNC operation interface. The operator can complete complex processing tasks through simple instructions. This not only improves the convenience of operation, but also reduces the possibility of human error and enhances the stability of the production line.

ALCK6166X1000 CNC lathe metal lathe is widely used in application industries:

1. Aerospace: In the aerospace field, the requirements for precision processing of parts are extremely high. The ALCK6166X1000 CNC lathe metal lathe has become a powerful assistant in the aerospace manufacturing process with its high precision and multi-functional processing capabilities. From aircraft engine parts to flight control system parts processing, the ALCK6166X1000 horizontal CNC lathe can handle it all.

2. Automobile manufacturing: In the automobile manufacturing industry, the ALCK6166X1000 horizontal CNC lathe is also widely used in the processing of parts such as engines, transmissions, and braking systems. Its efficient production capacity and precise processing technology provide key production guarantees for automobile manufacturing.

3. General machinery manufacturing: ALCK6166X1000 horizontal CNC lathe also performs well in the field of general machinery manufacturing. In the production process of various mechanical parts, the ALCK6166X1000 horizontal CNC lathe meets the production needs of different industries through its flexible and diverse processing capabilities, and promotes the development of general machinery manufacturing industry.

ALCK6160×1000 automatic cnc lathe standard configuration:

1. Ordinary main motor

2. Domestic frequency converter

3. Three-jaw chuck

4. Tailstock

5. Four-station electric knife holder

6. Automatic lubrication system

7. Electric cooling system

8. Lighting system

9. Semi-enclosed shield

10. Electrical control components

11. A full set of technical information

12. Random standard accessories and tools

ALCK6160×1000 automatic cnc lathe optional configuration:

1.Integral bed foot

2.Eight-station electric knife holder

3.Hydraulic Chuck

4.Electric chuck

5.Hydraulic tailstock

6.Center bracket

7.Frequency conversion motor

8.Servo motor

9.Electric gate

video:

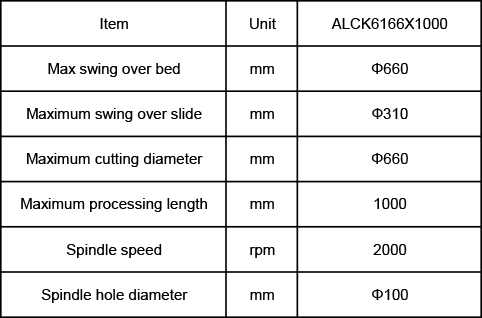

Product parameters: