PRODUCT

ALCK6166X1500 cnc lathe

ALCK6166×1500 CNC lathe controls various processing of the machine tool. The vertical and horizontal feeds are driven by AC servo motors, and the automatic rotary tool holder or row tool is used. It can be equipped with manual or hydraulic chucks. This machine tool is especially suitable for the processing of large and medium batches of multi-step shafts and sleeve parts, and can also be used for automatic turning of taper, arc, thread and other parts.

ALCK6166×1500 full-featured CNC lathe has stepless speed change, the motor is transmitted to the main shaft through the pulley through the gear, and is controlled by the numerical control system to realize stepless speed regulation. The head of the main shaft is equipped with a manual chuck or a hydraulic chuck, which is convenient for loading and unloading parts and reliable in use.

ALCK6166X1500 flat bed CNC lathe features:

1. High-precision processing: ALCK6166X1500 horizontal CNC lathe has excellent processing accuracy and can achieve high-precision workpiece processing to ensure product quality and consistency.

2. Large processing size: ALCK6166X1500 horizontal CNC lathe has large processing size and is suitable for processing large workpieces, such as bearings, turbine parts, engineering machinery parts, etc.

3. Multi-process processing: Supports a variety of processing techniques, including turning, boring, milling, drilling, tapping, etc., suitable for multi-functional processing of complex workpieces.

4. Automated control: ALCK6166X1500 CNC lathes and milling machines are equipped with advanced CNC systems, which can realize automated processing, improve production efficiency, and reduce operator intervention.

5. Stable and reliable: ALCK6166X1500 flat bed CNC lathe is made of solid structure and high-quality materials, providing stable performance and durability for long-term operation.

6. Easy to operate: It has a humanized operating interface and programming system, allowing operators to easily learn and master the operation of CNC lathes.

ALCK6166×1500 horizontal cnc lathe use:

1. Railway locomotive manufacturing industry: ALCK6166×1500 automatic cnc lathe is aimed at high-speed rail locomotive body, axle, wheel and other parts.

2. Mold processing and manufacturing industry: The precision of parts is required to be high, and the surface precision mainly refers to the surface roughness. Cylindrical parts with high requirements for cylindricity; conical parts with high requirements for plain straightness, roundness and inclination; rotary parts with special threads. ALCK6166×1500 automatic cnc lathe can better solve this problem.

3. Defense industry: The ability of ALCK6166×1500 automatic cnc lathe to provide replacement parts and upgrade components on demand is especially useful in this industry. Therefore, it is suitable for components that require continuous innovation and safety.

4. Medical business field: ALCK6166×1500 flat bed cnc lathe can be used in various medical safety materials. Since the process is suitable for one-off custom parts, it has many applications in the medical industry. The tight tolerances offered by ALCK6166×1500 flat bed cnc lathe machining are essential for high performance machining of medical components.

ALCK6166×1500 turning cnc lathe standard configuration:

1. CNC system

2. Four-station electric knife holder

3. Ordinary three-jaw chuck

4. Ordinary tailstock

5. Frequency conversion main motor

6. Cooling system, automatic lubrication

ALCK6166×1500 turning cnc lathe optional configuration:

1. Same server main motor

2. Pneumatic or hydraulic chuck

3. Pneumatic hydraulic collet

4. Six or eight station tool post

Video:

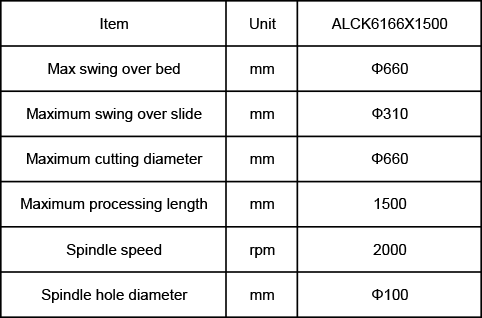

Product parameters: