PRODUCT

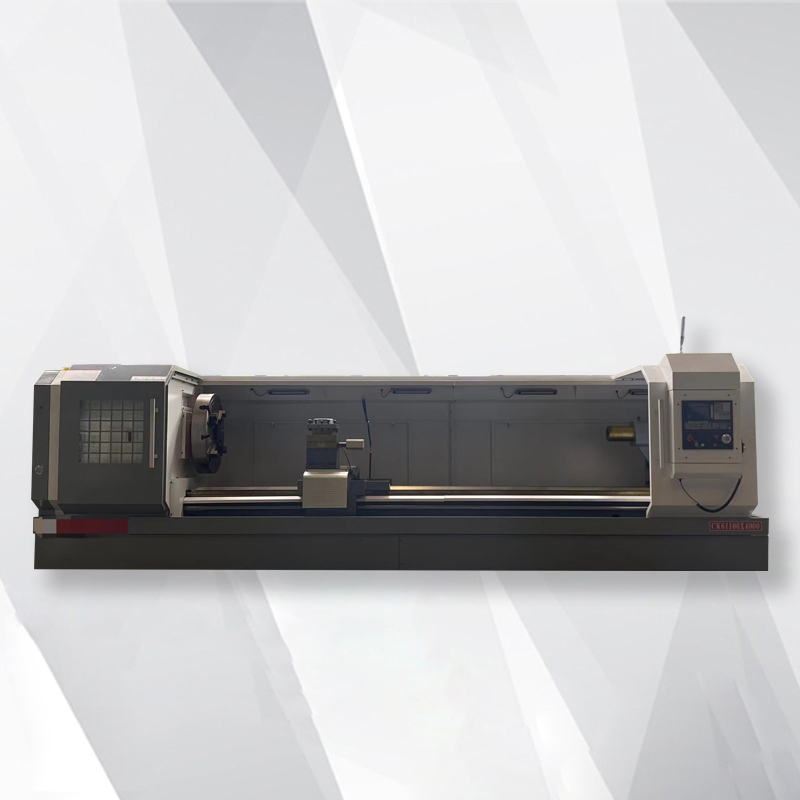

ALCK61100x4000 CNC horizontal lathe

ALCK61100x4000 CNC horizontal lathe has the characteristics of high precision, high power and high rigidity. Its main components and structure have been optimized and designed. ALCK61100x4000 CNC horizontal lathe spindle system structure adopts manual four-speed transmission, which has good impact resistance, good stability and good cutting performance. ALCK61100x4000 automatic CNC lathe has low noise, strong adaptability to batch processing of large, medium and small batches, multi-variety and multi-specification parts, and the processing quality is stable and reliable. ALCK61100x4000 automatic CNC lathe can automatically complete the turning of internal and external circles, end faces, grooving, arbitrary tapers, curved surfaces, metric cylinders, conical threads and other processes of parts.

The key components of the ALCK61100x4000 automatic CNC lathe are made of high-quality materials. The bed, spindle box, feed box, slide and other components are all made of high-quality high-strength cast iron and have undergone long-term aging treatment to ensure the accuracy and stability of the parts. The machine tool configuration enjoys a high reputation in the country. The brand's four-station digital control tool holder has the characteristics of high positioning accuracy, high strength, and good shock resistance. The ALCK61100x4000 flat bed CNC lathe machine tool is inspected strictly in accordance with the inspection procedures before leaving the factory to ensure the accuracy, stability and reliability of the machine tool.

The metal CNC lathe ALCK61100X4000 is an efficient and high-precision processing equipment with many unique features:

1. The metal CNC lathe ALCK61100X4000 adopts digital control technology, which can realize automated processing operations and greatly improve work efficiency.

2. The metal CNC lathe ALCK61100X4000 has a large processing capacity and can process workpieces with a diameter of 1100 mm and a length of 4000 mm, and is suitable for processing larger-sized workpieces.

3. The flat bed CNC lathe ALCK61100X4000 also has a multi-station turret system, which can realize the switching of multi-station tools to adapt to different processing needs.

4. The flat bed CNC lathe ALCK61100X4000 also has high-precision processing capabilities, which can achieve micron-level high-precision processing and ensure the quality and accuracy requirements of processed parts.

5. The horizontal CNC lathe ALCK61100X4000 is also equipped with an advanced cooling system, which can effectively reduce thermal deformation during processing and improve processing stability.

6. The horizontal CNC lathe ALCK61100X4000 has good rigidity and stability and can withstand large cutting forces to ensure the stability and reliability of the processing process.

ALCK61100x4000 CNC metal application industry:

1. Aerospace industry: ALCK61100x4000 CNC lathe plays an important role in the aerospace field and is used to process aircraft parts, engine parts, etc.

2. Automobile manufacturing industry: ALCK61100x4000 CNC lathe In automobile manufacturing, CNC lathes are often used to process key parts such as engine parts, transmission parts, wheels, etc.

3. Energy industry: ALCK61100x4000 CNC lathe is used to process energy equipment, such as turbine parts for power plants, oil and gas extraction equipment, etc.

4. General machinery manufacturing industry: ALCK61100x4000 CNC lathe can be used to process various general mechanical parts, such as bearings, gears, connecting rods, etc.

5. Mold manufacturing industry: ALCK61100x4000 Fanuc CNC lathe is used to manufacture molds and mold parts to meet the specific shape and size requirements of other industries.

6. Railway transportation: ALCK61100x4000 Fanuc CNC lathe is used to process railway vehicle parts, such as axles, wheels, etc.

Shipbuilding industry: ALCK61100x4000 Fanuc CNC lathe is used to process ship structures and parts, including hulls, propulsion systems, etc.

ALCK61100x4000 CNC horizontal lathe standard configuration:

1. Spindle and spindle drive system: The powerful spindle motor and corresponding transmission system provide sufficient processing power.

2. Lathe bed and bed guide rail: A lathe bed with sufficient rigidity and stability usually adopts cast iron or welded structure. The bed guide rails can be linear guide rails or inclined bed guide rails.

3. Control system: Equipped with Siemens, Fanuc, Mitsubishi and other CNC systems.

4. Tool Tower: Equipped with a tool tower that can automatically switch and install tools to improve production efficiency.

5. Automatic lubrication system: used to automatically lubricate key components such as bed guide rails and screw rods to ensure smooth operation of the machine tool.

Optional configurations of ALCK61100x4000 CNC horizontal lathe:

1. Automatic tool changing system: It can automatically change different types of tools to improve processing flexibility and efficiency.

2. Automatic measurement system: It can automatically measure the size of the workpiece and realize automatic size control.

3. Processing cooling system: For special process requirements, a more advanced cooling system can be configured to ensure stability during high-speed cutting.

4. Automatic loading and unloading system: used to automatically load and unload workpieces to improve production efficiency.

5. Tools and tool library: A larger-capacity tool library supports more different types of tools.

6. Advanced CNC system: Upgrade to a higher-level CNC system to provide more functions and higher control accuracy.

7. Processing monitoring system: It can monitor tool wear, temperature and other parameters to improve the controllability of the production process.

Product parameters: