PRODUCT

ALCK6163X1500 cnc lathe machine

ALCK6163X1500 CNC lathe is an economical and practical high-end processing machine tool with mature product structure, stable performance and quality, and can perform repeated cycle processing. It is widely used in mechanical processing in various industries such as automobiles and petroleum. This series of machine tools can realize the inner and outer surfaces of shafts and disks, as well as the processing of conical surfaces, arcs, threads, boring holes and reaming holes, as well as non-circular curve processing.

CK6163X1500 CNC lathe is suitable for processing complex-shaped rotary parts, and can process cylindrical surfaces, curved surfaces, conical surfaces, and stepped surfaces; various internal and external threads, drilling, reaming, reaming and rolling, etc., especially suitable for processing large quantities of parts . The casting is made of resin sand material, the casting has high dimensional accuracy, strong rigidity, good surface quality, wear resistance, stability, vibration resistance, and stable continuous processing.

CNC lathe ALCK6163X2000 has the following features:

1. High-precision machining capabilities: Equipped with an advanced CNC system, it has precise positioning control and high-speed cutting capabilities, which can achieve high-precision machining requirements.

2. Large workpiece processing capacity: It has a large processing stroke and processing diameter, suitable for processing large workpieces, and can meet the processing requirements of larger parts.

3. Multi-functional processing: Various processing methods can be realized through different combinations of tools and tool holders, including turning, boring, drilling and other processing functions.

4. Efficient production: It has a high degree of automation and can realize continuous processing and automatic tool changing, improving production efficiency.

5. Easy to operate: Equipped with an intuitive and easy-to-understand CNC operation interface, the operation is simple and convenient, reducing the technical requirements of the operator.

6. High reliability: Using high-quality mechanical transmission components and a stable and reliable CNC system, it has high stability and reliability.

7. Strong adaptability: suitable for processing various materials, including metals, plastics, ceramics and other materials, and widely used in machinery manufacturing, aerospace, automobiles and other fields.

ALCK6163×1500 horizontal cnc lathe use:

1. Railway locomotive manufacturing industry: ALCK6163×1500 automatic cnc lathe is aimed at high-speed rail locomotive body, axle, wheel and other parts.

2. Mold processing and manufacturing industry: The precision of parts is required to be high, and the surface precision mainly refers to the surface roughness. Cylindrical parts with high requirements for cylindricity; conical parts with high requirements for plain straightness, roundness and inclination; rotary parts with special threads. ALCK6163×1500 automatic cnc lathe can better solve this problem.

3. Defense industry: The ability of ALCK6163×1500 automatic cnc lathe to provide replacement parts and upgrade components on demand is especially useful in this industry. Therefore, it is suitable for components that require continuous innovation and safety.

4. Medical business field: ALCK6163×1500 flat bed cnc lathe can be used in various medical safety materials. Since the process is suitable for one-off custom parts, it has many applications in the medical industry. The tight tolerances offered by ALCK6163×1500 flat bed cnc lathe machining are essential for high performance machining of medical components.

ALCK6163×1500 turning cnc lathe standard configuration:

1. CNC system

2. Four-station electric knife holder

3. Ordinary three-jaw chuck

4. Ordinary tailstock

5. Frequency conversion main motor

6. Cooling system, automatic lubrication

ALCK6163×1500 turning cnc lathe optional configuration:

1. Same server main motor

2. Pneumatic or hydraulic chuck

3. Pneumatic hydraulic collet

4. Six or eight station tool post

video:

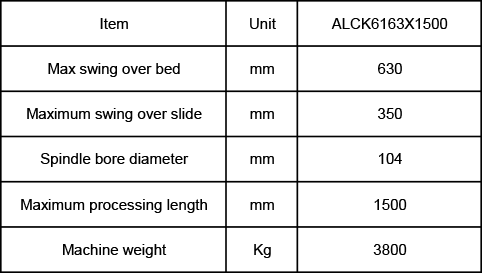

Product parameters: