PRODUCT

ALTCK6350 cnc lathe machine

Inclined bed CNC lathe TCK6350 cnc lathe machine performs batch, high-efficiency, high-precision automatic processing on the conical surface, arc surface, end surface and various metric and inch threads of rotary parts. It adopts a 45-degree high-rigidity integral bed and a high-precision spindle unit. using Taiwan line rails to ensure the highrigidity of the whole machine, the center of the spindle is close to theoperator, and it is more convenient to load and unload the workpiece.

TCK6350 slanted bed CNC lathe is a high-speed, high-reliability slanted bed machine bed, bed, bedside box and other main components are cast from high-strength materials to ensure the long-term stability of the machine tool. 45° overall inclined bed structure, the machine tool has high positioning accuracy, smooth chip removal, suitable for high-speed and high-finish machining. Indoor assembly, 72 hours of continuous running-in at constant temperature after assembly, and 72 hours of continuous trial operation after being put on the machine to ensure reliable high-speed and high-precision performance. The factory arrangement method is adopted, with fast tool change speed and high positioning accuracy.

CNC lathe ALTCK6350 has the following features:

1. High precision: The use of CNC control system can achieve precise processing and ensure the dimensional accuracy and surface quality of processed parts.

2. High efficiency: It has automated processing functions and can realize continuous processing operations, greatly improving production efficiency.

3. Multi-function: Equipped with a variety of processing functions, it can realize a variety of processing operations such as turning, boring, drilling, etc., to meet different workpiece processing needs.

4. Good stability: The whole machine has a stable structure and little vibration during processing, which can ensure processing accuracy and surface quality.

CNC lathe ALTCK6350 has a wide range of applications in multiple industries, including:

1. Machinery manufacturing: Horizontal CNC lathe ALTCK635 is suitable for automobile manufacturing, aerospace, mold manufacturing and other fields. It can process various parts, such as engine parts, aircraft structural parts, mold parts, etc.

2. Railway transportation: The horizontal CNC lathe ALTCK635 can be used in the field of rail transportation to process parts such as railway bearings, rails, couplings, etc. to ensure its accuracy and reliability.

3. Petrochemical industry: ALTCK6350 CNC lathe can process key components of petrochemical equipment, such as valves, pipe joints, pump bodies, etc., to ensure the sealing and safety of the equipment.

4. Electronic instruments: CNC lathe ALTCK6350 can process precision electronic instrument parts, such as connectors, conductive plug-ins, audio sockets, etc., meeting the requirements of high precision and reliability.

ALTCK6350 cnc lathe machine standard configuration:

1. Servo main motor

2.140 mm spindle unit (3500 rpm)

3. Taiwan Straight Line Railway

4. Ball screw

5. Hydraulic chuck

ALTCK6350 slanted bed CNC lathe optional configuration:

1. Spindle unit

2. Ball screw

3.6/8 station electric turret

4.8/12 station hydraulic turret

5. Hydraulic Chuck

6. Chip conveyor

video:

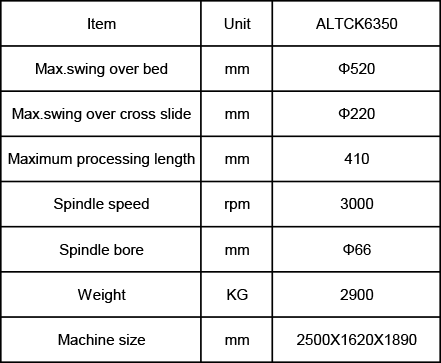

Product parameters: