PRODUCT

ALVMC640 Vertical Machining Center

The ALVMC640 Vertical Machining Center is a compact and versatile CNC milling machine designed for high-precision machining of small to medium-sized parts. With excellent rigidity, precise motion control, and stable performance, it is ideal for industries requiring precision components with high surface quality. It is well suited for mold processing, batch parts production, and educational or R&D institutions.

ALVMC640 Vertical Machining Center – Product Introduction

The ALVMC640 adopts a high-rigidity cast iron base and column structure, providing stable support during cutting. It is equipped with a servo spindle and linear guideways, ensuring smooth operation and consistent accuracy. With its compact footprint, the machine fits well in space-constrained workshops while maintaining high productivity. The standard automatic tool changer and centralized lubrication system enhance automation and reduce downtime.

Main Features:

l Rigid cast iron frame and column for stable machining

l Precision linear guideways for high accuracy and smooth motion

l Compact size, ideal for limited space workshops

l Servo spindle with high torque and fast acceleration

l 16-tool automatic tool changer for flexible machining

l Centralized lubrication system to reduce maintenance

l Optional 4th axis rotary table for complex part processing

Application Industries:

1. Mold Manufacturing

Ideal for precision cavity and core machining in plastic and die-casting molds.

2. Automotive Components

Used for machining brackets, housings, and transmission-related parts.

3. Precision Hardware

Suitable for producing high-precision fittings, fasteners, and structural parts.

4. Electronics & Communication

For machining aluminum panels, connectors, and device enclosures.

5. Education & Research

Widely used in training centers and R&D labs for CNC process teaching and prototype development.

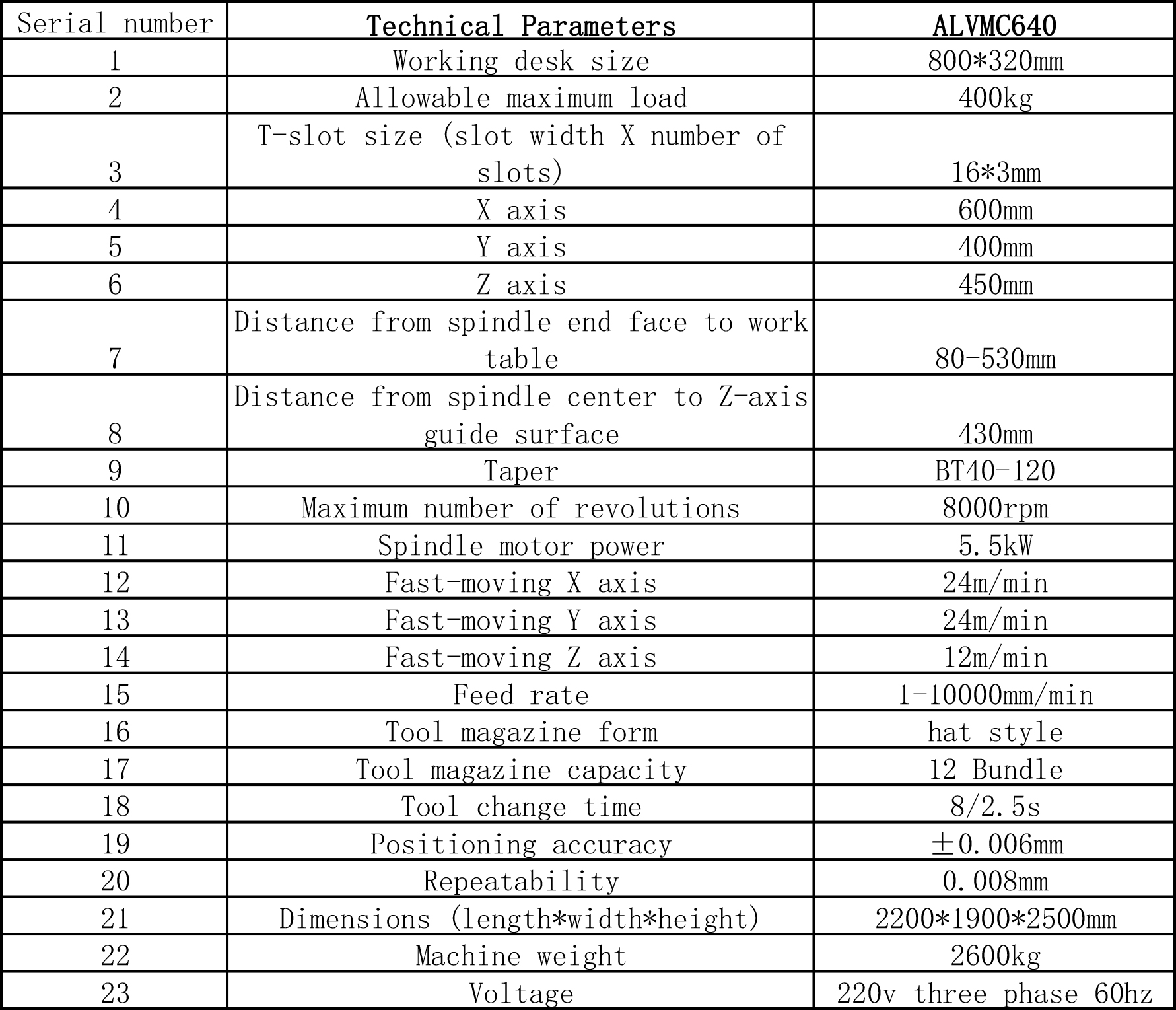

Product Parameters: