PRODUCT

ALFCK40 Slant Bed CNC Lathe

The ALFCK40 slant-bed CNC lathe is a high-precision, high-rigidity CNC turning machine. Its 45° slant bed ensures smooth chip evacuation and stable cutting, making it ideal for high-speed, high-precision metal cutting. Equipped with a high-performance spindle, precision ball screw, and servo drive system, the machine ensures consistent machining accuracy over time. It can complete multiple machining operations, including external diameters, end faces, tapers, threads, and internal bores, in a single clamping setup, significantly improving production efficiency. This machine is widely used in industries such as machinery manufacturing, automotive parts, aerospace, and precision instruments, and is particularly well-suited for mass production and high-precision machining of small and medium-sized precision parts.

ALFCK40 Slant Bed CNC Lathe – Product Introduction

Overview:

The ALFCK40 slant bed CNC lathe is a high-precision, high-rigidity CNC turning machine designed with a 45° slant bed structure to improve chip removal efficiency and cutting stability. It is particularly suitable for high-speed, high-precision metal cutting applications. The compact overall structure saves floor space, while the high-performance servo drive system, precision ball screws, and rigid spindle ensure consistent machining accuracy during long-term operation. The advanced CNC system supports a variety of automated machining programs, enabling one-time clamping to complete turning of outer diameters, end faces, tapers, threads, and internal holes, greatly improving production efficiency. This lathe is ideal for mass production of small and medium-sized precision parts as well as high-accuracy single-piece machining.

Main Features

-

Slant bed design – 45° integral slant bed allows natural chip flow, improving chip removal efficiency and reducing thermal deformation.

-

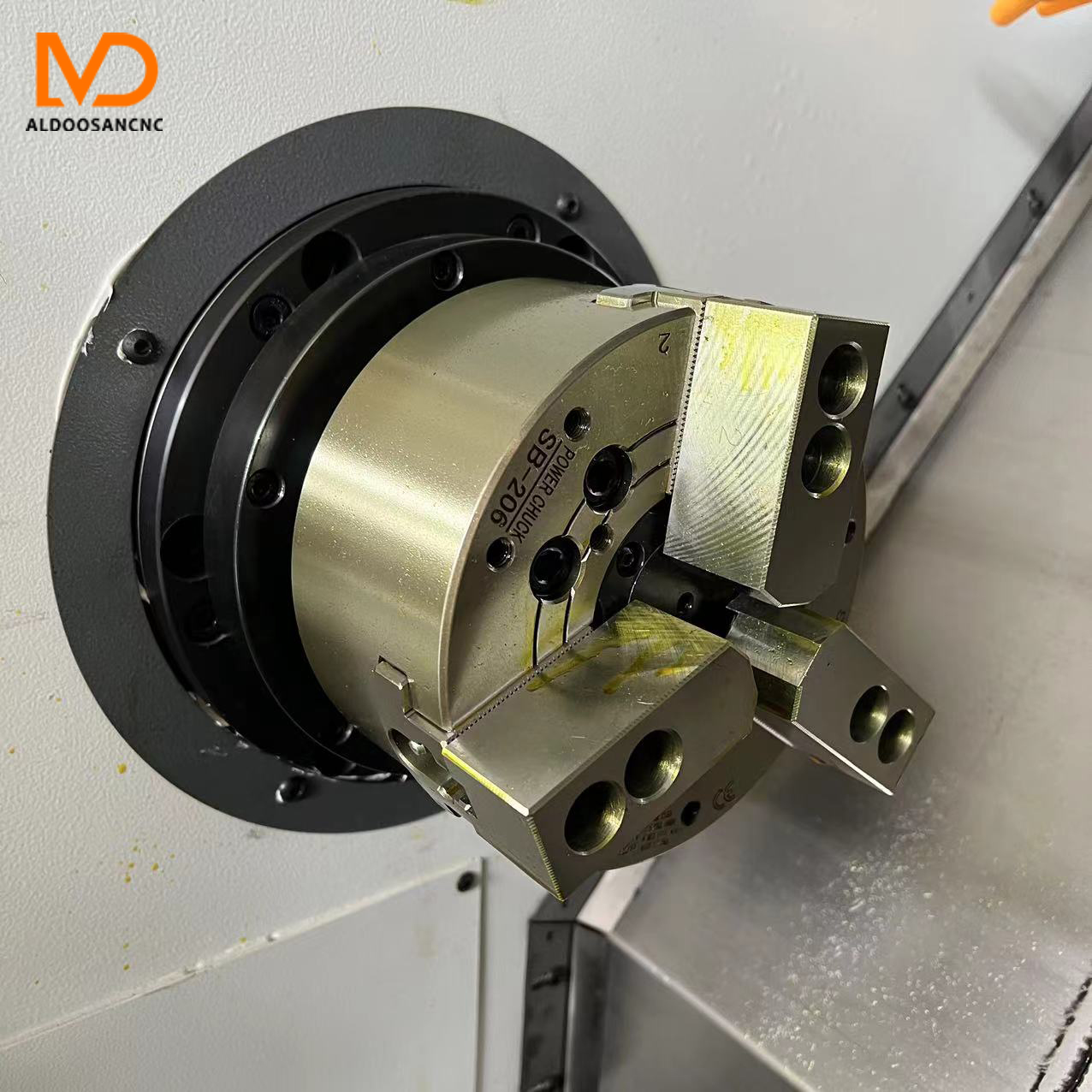

High-rigidity spindle – Supported by high-precision bearings, offering high speed, high torque, and strong adaptability to various metals.

-

Precision transmission system – All axes equipped with precision ball screws and servo drives, ensuring high positioning and repeatability accuracy.

-

Stable cutting performance – Strong cutting rigidity for both heavy-duty and high-precision machining.

-

High efficiency – One-time clamping for multiple operations, minimizing repositioning errors.

-

Intelligent CNC system – Supports multiple programming languages and automated control for flexible machining.

-

Easy maintenance – User-friendly interface and well-structured design for convenient daily operation and maintenance.

Application Industries

-

Machinery manufacturing – Precision machining of small and medium-sized shafts, disks, and bushings.

-

Automotive manufacturing – Engine shafts, gearbox parts, brake components, and connectors.

-

Aerospace – High-precision small shafts, sleeves, connectors, and brackets.

-

Precision instruments – Optical instrument parts, measuring instrument components, and micro-mechanical parts.

-

Electronics & medical devices – Precision electronic connectors, medical instrument parts, and small metal fittings.

Product Parameters:

| Category | Item | Unit | Specification |

| Standard Configuration | Ball screw & linear guide | – | Japan THK ball screw, Taiwan Hiwin guide (custom order) |

| Turning Capacity | Max. swing diameter | mm | Ø400 |

| Swing over cross slide | mm | Ø120 | |

| Max. turning length | mm | 400 | |

| Max. bar through-hole | mm | Ø42 | |

| Workholding | Work piece clamping method | N/A | Collet chuck |

| Spindle | Spindle speed range | rpm | Optional: 100–3000 (standard) / 100–4000 (precision) |

| Spindle nose size | N/A | A2-5 | |

| Rapid Feed | X-axis rapid traverse | m/min (mm/min) | 24m (3210) |

| Z-axis rapid traverse | m/min (mm/min) | 24m (3210) | |

| Travel | X-axis travel | mm | 800 |

| Z-axis travel | mm | 420 | |

| Precision | X/Z-axis repeat positioning accuracy | mm | 0.003 |

| Tool System | Toolholder type | N/A | Gang-type |

| Tool size | mm | 20 | |

| Max. number of tools | pcs | 9 (compatible with 63-position turret) | |

| Others | Overall size (L×W×H) | mm | 2100 × 1450 × 1850 |

| Bed bottom spindle center height | mm | 990 | |

| Net weight | kg | Approx. 1500 |