PRODUCT

ALVMC1160 cnc machine center

The main components of the ALVMC1160 metal processing center are optimized by finite element analysis. The main cast iron is made of high-strength cast iron with stable metallographic structure. After aging, sandblasting, tempering and other processes, the stability of the long-term use accuracy of the machine tool is ensured.

The ALVMC1160 metal processing center spindle adopts a pneumatic mechanism to drive the spindle, and the spindle is evenly stressed during the strike, prolonging the life of the bearing. The electrical box adopts an internal isolation design to separate the heat source part of the controller. The front uses a heat exchanger to dissipate heat to prevent external dust from entering the electrical box; the rear uses a fan to dissipate heat from the fan heat plate. The three-axis adopts high-precision quenched screw, combined with precision nut preloading and tail pre-tensioning device, to ensure that the backlash and thermal deformation of the machine are kept at a low value for a long time. X, Y, and Z axes adopt roller-type linear guide rails, which have high rigidity and low noise, and can perform rapid displacement and obtain the best cycle accuracy. All finished products have undergone laser positioning correction and circular testing to ensure the best positioning accuracy and servo characteristics, and the machine has undergone strict inspection measures before shipment to ensure the long-term stability of the accuracy of the machine.

Features of ALVMC1160 CNC Machining Center:

1. The head group is a heavy-duty box structure with internal rib reinforcement and high rigidity.

2. The spindle is evenly stressed when cutting the knife, prolonging the life of the bearing.

3. The electrical box adopts an internal isolation design to separate the heat source part of the controller. The front uses a heat exchanger to dissipate heat to prevent external dust from entering the electrical box; the rear uses a fan to dissipate heat from the fan heat plate.

4. The three-axis adopts high-precision quenched screw, combined with precision nut preloading and tail pre-tensioning device, to ensure that the backlash and thermal deformation of the machine are kept at a low value for a long time.

5. With high rigidity and low noise, it can do fast displacement and obtain the best cycle accuracy.

ALVMC1160 CNC machine tool metal milling application:

1. Parts processing: ALVMC1160 CNC machine tool metal milling is widely used in parts processing fields of automobile, aerospace, electronics and other industries. It can efficiently and precisely process various parts with complex shapes, such as gears, threads, apertures, etc., to meet the requirements of industrial manufacturing

2. Mold processing: Mold manufacturing is a part of modern manufacturing industry. ALVMC1160 CNC machine metal milling CNC lathe has advantages in the field of mold processing. It can realize multi-angle and multi-axis processing, and improve the precision and efficiency of mold making

3. Steel processing field: ALVMC1160 CNC milling machine can be used to process bearings, bushings, journals and other parts to improve production efficiency and product quality. Its excellent performance and reliability make it a key tool in the processing field and promote the development and progress of related industries.

4. In the field of power generation equipment: ALVMC1160 CNC milling machine is widely used in the processing of key components of wind power generators, such as horizontal spindles, wind wheels, gearboxes, generators, etc. The processing is difficult and requires high precision. CNC machine tools can better solve complex, precise, small batch and multi-variety parts processing problems.

Standard configuration of ALVMC1160 CNC machining center:

1. System: servo system

2. Main motor

3. Feed motor: KND same service motor.

4. Spindle high speed and high precision spindle unit

5. Lead screw

6. Tool magazine: Taiwan Desu disc tool magazine with a capacity of 24 knives

7. Machine tool lighting

Optional configuration of ALVMC1160 CNC machining center:

1. Shaft hard rail

2. Axis rail

3. 6000 rpm domestic spindle

4. Spindle center water outlet

5. Spindle oil cooling

6. Bucket tool magazine

7. Disk magazine

8. FANUC system

9. CNC dividing head

10. CNC rotary table

11. Bridge plate combination turntable

12. CNC five-axis turntable

Video:

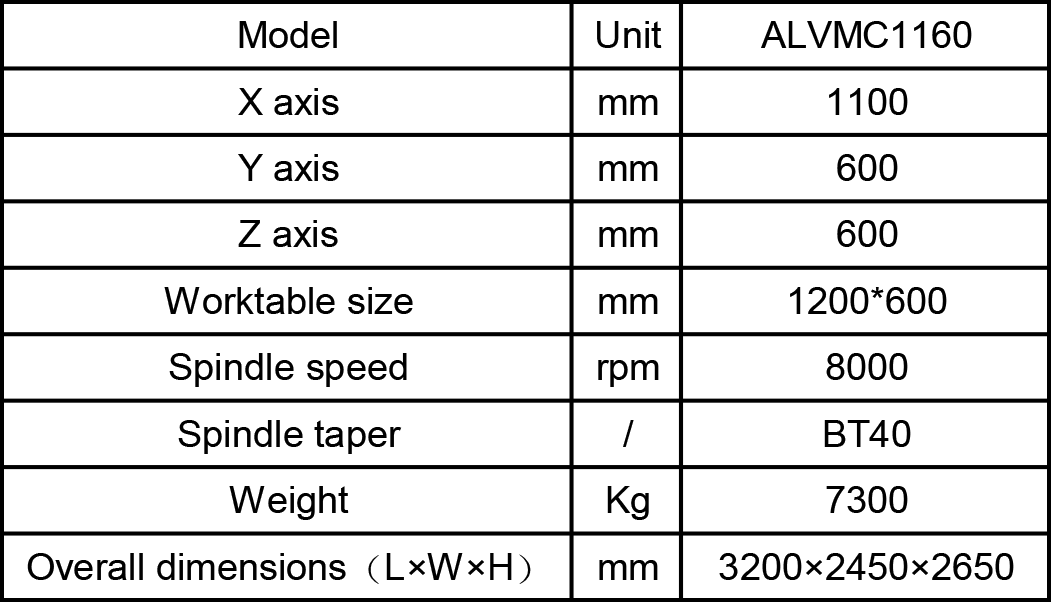

Product parameters: