PRODUCT

ALVMC1160 cnc machine center

The main components of the ALVMC1160 metal processing center are optimized by finite element analysis. The main cast iron is made of high-strength cast iron with stable metallographic structure. After aging, sandblasting, tempering and other processes, the stability of the long-term use accuracy of the machine tool is ensured.

The ALVMC1160 metal processing center spindle adopts a pneumatic mechanism to drive the spindle, and the spindle is evenly stressed during the strike, prolonging the life of the bearing. The electrical box adopts an internal isolation design to separate the heat source part of the controller. The front uses a heat exchanger to dissipate heat to prevent external dust from entering the electrical box; the rear uses a fan to dissipate heat from the fan heat plate. The three-axis adopts high-precision quenched screw, combined with precision nut preloading and tail pre-tensioning device, to ensure that the backlash and thermal deformation of the machine are kept at a low value for a long time. X, Y, and Z axes adopt roller-type linear guide rails, which have high rigidity and low noise, and can perform rapid displacement and obtain the best cycle accuracy. All finished products have undergone laser positioning correction and circular testing to ensure the best positioning accuracy and servo characteristics, and the machine has undergone strict inspection measures before shipment to ensure the long-term stability of the accuracy of the machine.

Features of ALVMC1160 CNC Machining Center:

1. High-precision processing: CNC metal milling machine ALVMC1160 has high-precision positioning and processing capabilities, and is suitable for processing parts requiring high precision. It enables precise milling, drilling and cutting operations on different materials.

2. Multi-axis processing: CNC metal milling machine ALVMC1160 usually has multiple coordinate axes, including X-axis, Y-axis and Z-axis, allowing processing in different directions, thereby increasing the processing flexibility of the workpiece.

3. Automation and intelligence: CNC metal milling machine ALVMC1160 is usually equipped with a CNC system, which can perform automated processing operations. It can also be integrated with CAD/CAM software to achieve higher production efficiency.

4. Rigid structure: CNC milling machine aluminum ALVMC1160 usually has a strong machine tool structure, which can withstand large cutting forces and ensure high-quality processing.

5. Wide range of applications: CNC milling machine aluminum ALVMC1160 is widely used in aerospace, automobile manufacturing, mold manufacturing, medical equipment manufacturing, electronic equipment manufacturing and general machinery manufacturing and other industries. It can be used to process a variety of metal and non-metal materials, including aluminum, steel, copper, plastic, etc.

6. Mass production: Due to its high precision and automation features, the CNC milling machine ALVMC1160 is often used in mass production and can process large quantities of parts quickly and accurately.

ALVMC1160 CNC machine tool metal milling application:

1. Aerospace industry: In the aerospace field, Chinese CNC milling machine ALVMC1160 is used to manufacture aircraft and spacecraft parts, such as engine parts, wings, spacecraft shells, etc. These parts often require high precision and complex geometries.

2. Automobile manufacturing industry: The automobile manufacturing industry widely uses the Chinese CNC milling machine ALVMC1160 to produce automobile parts, including engine parts, suspension systems, braking systems and body structure components. These parts require high precision and quality.

3. Mold manufacturing industry: The field of mold manufacturing requires high-precision parts processing. The Chinese CNC milling machine ALVMC1160 is used to manufacture injection molds, die-casting molds, stamping molds and precision molds, etc.

4. Medical equipment manufacturing industry: In medical equipment manufacturing, the vertical CNC milling machine ALVMC1160 is used to manufacture various medical equipment parts, including surgical instruments, microscope parts, dental equipment and prostheses, etc.

5. Electronic equipment manufacturing: Electronic equipment manufacturing requires the manufacture of precision electronic parts and circuit boards. The vertical CNC milling machine ALVMC1160 can be used to process electronic equipment casings, radiators, circuit board brackets, etc.

6. General machinery manufacturing industry: The vertical CNC milling machine ALVMC1160 can be used to manufacture various general mechanical parts, such as bearing seats, gears, pins, connecting rods, etc. These parts are widely used in various mechanical equipment.

7. Shipbuilding industry: In shipbuilding, CNC machining center ALVMC1160 is used to manufacture hull parts, steering gear parts, ship engine parts, etc.

Standard configuration of ALVMC1160 CNC machining center:

1. System: servo system

2. Main motor

3. Feed motor: KND same service motor.

4. Spindle high speed and high precision spindle unit

5. Lead screw

6. Tool magazine: Taiwan Desu disc tool magazine with a capacity of 24 knives

7. Machine tool lighting

Optional configuration of ALVMC1160 CNC machining center:

1. Shaft hard rail

2. Axis rail

3. 6000 rpm domestic spindle

4. Spindle center water outlet

5. Spindle oil cooling

6. Bucket tool magazine

7. Disk magazine

8. FANUC system

9. CNC dividing head

10. CNC rotary table

11. Bridge plate combination turntable

12. CNC five-axis turntable

Video:

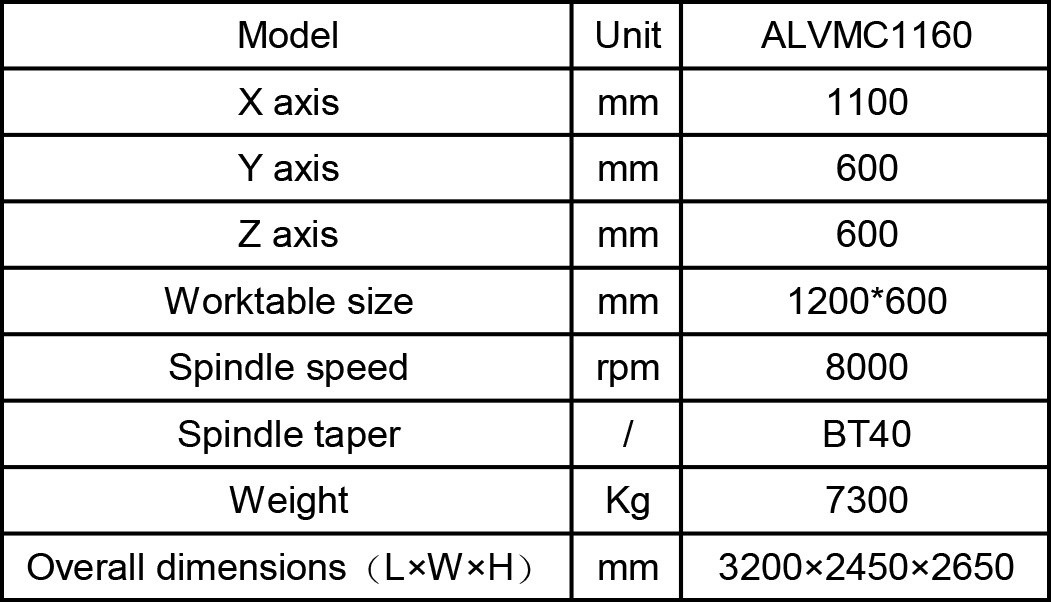

Product parameters: