PRODUCT

ALCK0640 cnc lathe machine

CK0640 CNC lathe adopts mechanical and electrical integration design, beautiful appearance, reasonable structure, wide range of uses, convenient operation, automatic control, and automatic processing of inner and outer circles, end faces, grooving, arbitrary conical surfaces, spherical surfaces, and various parts of various parts. Metric cylindrical, conical screw

This machine tool adopts the design of electromechanical integration, which can automatically complete the inner and outer circles, end faces, grooving, chamfering, drilling, arbitrary

Conical surface, spherical surface and various inch and metric thread cutting. Widely used in automobile and motorcycle accessories, valves, plumbing pipes, hardware

Tools, watches and electrical appliances, aviation electronics and other industries processing. It is the most ideal high-efficiency equipment in the hardware machining industry.

ALCK0640 horizontal cnc lathe machine features:

1. Automatic feeding in place detection, avoiding many collisions and knife strikes, and automatic processing is safer and more reliable;

2. Spindle positioning greatly expands the range of automatic processing and reduces production costs;

3. According to product requirements, online size detection function and clamping position detection can also be developed;

4. The guide rail is super-audio frequency quenched, with good wear resistance;

5. Adopt fully automatic centralized lubrication system;

6. Modular circuit design, more stable machine performance;

7. The full protection system of the machine tool sheet metal is movable, which fully guarantees the safety of the operator and the convenience of operation;

8. Using CNC blades, the machining accuracy is stable, the product quality is reliable, the blade life is long, the replacement is convenient, and the tool cost is saved;

9. ALCK0640, which can turn inner and outer cylindrical surfaces, conical surfaces, metric/inch threads, etc.; it can meet different needs of turning processing.

ALCK0640 horizontal cnc lathe machine application:

1. In the field of power generation equipment: ALCK0640 cnc metal lathe is widely used in the processing of key components of wind turbines, such as horizontal spindles, wind wheels, gearboxes, generators, etc., which is difficult to process and requires high precision. CNC machine tools can better solve this problem. Solved complex, precise, small batch, multi-variety parts processing problems.

2. Metallurgical equipment field: ALCK0640 cnc metal lathe is widely used in the processing of key components such as turning, drilling, reaming, boring, expanding, forming cutting, knurling and thread cutting and other workpieces that are difficult to process.

3. In the field of construction machinery: ALCK0640 cnc metal lathe is widely used in the processing and utilization of workpieces including shafts, gears, bushes, flywheels, cams, molds, and spiral prizes.

4. Railway locomotive manufacturing industry: ALCK0640 horizontal cnc lathe is widely used in the processing of high-speed rail locomotive car bodies, axles, wheels and other parts.

ALCK0640 cnc turning center standard configuration:

1. The numerical control system adopts FANUC numerical control system;

2. X-axis and Z-axis adopt three-phase hybrid stepping drive;

3. X-axis and Z-axis use ball screw;

4. The spindle is continuously variable;

5. The row tool holder has no tailstock;

6. The guide rail and screw rod of the machine tool adopt manual centralized lubrication;

7. Closed protection of machine tools.

ALCK0640 horizontal cnc lathe optional configuration:

1. Claw chuck;

2. Manual tailstock

3. Chuck;

4. Arranging tools;

5. Positioning tool;

6. Siemens CNC system.

video:

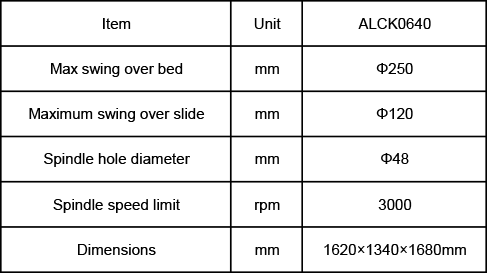

Product parameters: