PRODUCT

ALCK0640 cnc lathe machine

CK0640 CNC lathe adopts mechanical and electrical integration design, beautiful appearance, reasonable structure, wide range of uses, convenient operation, automatic control, and automatic processing of inner and outer circles, end faces, grooving, arbitrary conical surfaces, spherical surfaces, and various parts of various parts. Metric cylindrical, conical screw

This machine tool adopts the design of electromechanical integration, which can automatically complete the inner and outer circles, end faces, grooving, chamfering, drilling, arbitrary

Conical surface, spherical surface and various inch and metric thread cutting. Widely used in automobile and motorcycle accessories, valves, plumbing pipes, hardware

Tools, watches and electrical appliances, aviation electronics and other industries processing. It is the most ideal high-efficiency equipment in the hardware machining industry.

ALCK0640 horizontal cnc lathe machine features:

1. CNC system: The flat bed CNC lathe ALCK0640 adopts a CNC system, which can control the movement of the tool and the processing process through pre-programmed instructions to achieve high-precision and repeatable processing operations.

2. High precision: The flat bed CNC lathe ALCK0640 usually has high-precision positioning and processing capabilities, and can process complex parts and high-precision requirements on the surface of the parts.

3. Multi-axis control: Flat bed CNC lathe ALCK0640 usually has the ability to control multiple axes, including the spindle and feed axis, allowing precise workpiece processing in different directions.

4. Automation: CNC lathes and milling machines ALCK0640 can realize automatic tool changing, automatic feeding, automatic cutting and other automatic functions to improve production efficiency.

5. Programmability: CNC lathe and milling machine ALCK0640 can be programmed to produce workpieces of various shapes and sizes, so it is very flexible and suitable for small and large batch production.

ALCK0640 horizontal cnc lathe machine application:

1. Machinery manufacturing industry: CNC lathe processing ALCK0640 is widely used in the machinery manufacturing industry for processing various metal and non-metal materials and manufacturing parts and components, such as gears, bearings, threads, etc.

2. Aerospace industry: In the aerospace industry, CNC lathe processing ALCK0640 is used to manufacture aircraft parts, spacecraft components, and high-precision instruments.

3. Automobile industry: CNC lathe processing ALCK0640 is used in the automobile industry to process engine parts, transmission system parts, brake system parts, etc.

4. Electronic manufacturing industry: The metal lathe ALCK0640 is also used to produce electronic components such as connectors, sockets and other small parts.

5. Medical device manufacturing: In the process of manufacturing medical equipment and instruments, the metal lathe ALCK0640 is used to process precision parts and components.

6. General machinery manufacturing industry: In general machinery manufacturing industry, metal lathe ALCK0640 is used to manufacture various mechanical components and equipment.

ALCK0640 cnc turning center standard configuration:

1. The numerical control system adopts FANUC numerical control system;

2. X-axis and Z-axis adopt three-phase hybrid stepping drive;

3. X-axis and Z-axis use ball screw;

4. The spindle is continuously variable;

5. The row tool holder has no tailstock;

6. The guide rail and screw rod of the machine tool adopt manual centralized lubrication;

7. Closed protection of machine tools.

ALCK0640 horizontal cnc lathe optional configuration:

1. Claw chuck;

2. Manual tailstock

3. Chuck;

4. Arranging tools;

5. Positioning tool;

6. Siemens CNC system.

video:

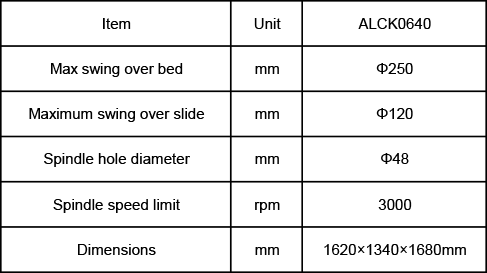

Product parameters: