PRODUCT

ALTCK36A slant bed cnc lathe

TCK36A slant bed cnc lathe inclined bed CNC lathe is suitable for processing all kinds of small and medium-sized shafts and disk parts, and can turn various threads, arcs, cones and inner and outer surfaces of rotary bodies. It is widely used in plumbing equipment bearings and other industries.

TCK36A slant bed cnc lathe is a high-speed, high-precision, high-reliability inclined bed machine tool. The main components of the bed base, bed, and headstock are all cast from high-strength materials to ensure the long-term stability of the machine tool. It adopts 45° overall inclined bed structure, and is equipped with high-precision preload linear rolling guide rails from Taiwan, China. The machine tool has high position accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining. High-speed, high-precision, high-rigidity shell-type spindle unit, servo spindle motor, can reach higher spindle speed. The tool changing speed is fast and the positioning accuracy is high. Adopting advanced centralized automatic lubrication device, timing and quantitative automatic intermittent lubrication, the work is stable and reliable. The machine tool protection adopts a full protection design, which is pleasant, beautiful, waterproof and chip-proof, reliable, and easy to maintain.

Features of ALTCK36A cnc lathe machining:

1. High-precision processing: The metal CNC lathe ALTCK36A is equipped with an advanced CNC system, which can achieve high-precision metal processing and ensure product quality and accuracy.

2. Stability and reliability: The metal CNC lathe ALTCK36A adopts high-quality materials and manufacturing processes, has excellent stability and reliability, and is suitable for long-term, high-intensity work.

3. Versatility: Metal CNC lathe ALTCK36A supports a variety of processing operations, including turning, boring, cutting, tapping, etc., and is suitable for the processing needs of workpieces of various shapes and sizes.

4. Ease of operation: The equipment is equipped with an intuitive CNC system interface, the operator can easily master the operation and improve work efficiency.

5. High production efficiency: CNC technology can realize automation and continuous processing, reduce human intervention and improve production efficiency.

Uses of ALTCK36A cnc lathe machining:

1. Machinery manufacturing industry: In the field of machinery manufacturing, metal CNC lathe ALTCK36A is often used to process various metal parts, such as bearings, gears, threads, etc.

2. Automobile manufacturing industry: In the automobile manufacturing industry, metal CNC lathe ALTCK36A is used to process key components such as engine parts, wheels, and braking systems.

3. Aerospace industry: Metal CNC lathe ALTCK36A can be used to manufacture aerospace engine parts, aircraft fuselage parts and spacecraft parts.

4. Energy field: In the energy field, it can be used to manufacture gas turbine parts, wind turbine parts, etc.

5. Medical equipment manufacturing: Used to manufacture medical equipment parts, such as artificial joints, surgical tools, etc.

6. Mold manufacturing: The high precision and versatility of the small CNC lathe ALTCK36A make it an ideal choice for manufacturing molds and tooling.

ALTCK36A cnc lathe machine standard configuration:

1 CNC controller

2. Linear guide rail

3. Spindle unit speed 4000rpm

4.6 inch hollow hydraulic chuck

5.8 station hydraulic turret

6. Automatic lubrication system

7. Automatic cooling system

8. Work lights

ALTCK36A cnc lathe machine optional configuration:

1. Hydraulic 4-jaw chuck

2. Servo Turret/Power Turret

3. Chip conveyor

4. FANUC CNC controller

video:

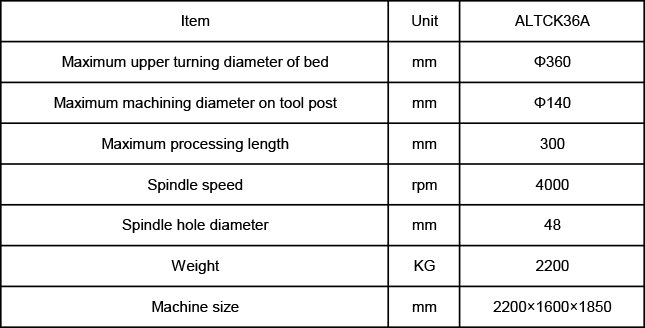

Product parameters: