PRODUCT

ALTCK36A slant bed cnc lathe

TCK36A slant bed cnc lathe inclined bed CNC lathe is suitable for processing all kinds of small and medium-sized shafts and disk parts, and can turn various threads, arcs, cones and inner and outer surfaces of rotary bodies. It is widely used in plumbing equipment bearings and other industries.

TCK36A slant bed cnc lathe is a high-speed, high-precision, high-reliability inclined bed machine tool. The main components of the bed base, bed, and headstock are all cast from high-strength materials to ensure the long-term stability of the machine tool. It adopts 45° overall inclined bed structure, and is equipped with high-precision preload linear rolling guide rails from Taiwan, China. The machine tool has high position accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining. High-speed, high-precision, high-rigidity shell-type spindle unit, servo spindle motor, can reach higher spindle speed. The tool changing speed is fast and the positioning accuracy is high. Adopting advanced centralized automatic lubrication device, timing and quantitative automatic intermittent lubrication, the work is stable and reliable. The machine tool protection adopts a full protection design, which is pleasant, beautiful, waterproof and chip-proof, reliable, and easy to maintain.

CNC lathe ALTCK36A is a high-performance CNC equipment with the following characteristics:

1. High-precision processing capabilities, capable of achieving precise processing of complex parts.

2. High-speed tool changing system improves production efficiency and processing quality.

3. Equipped with automated production functions, which can reduce labor costs and improve production efficiency.

4. Equipped with an intelligent control system, it is easy to operate, easy to learn and use.

5. Suitable for processing various materials, with good versatility and applicability.

Uses of ALTCK36A cnc lathe machining:

1. Railway locomotive manufacturing industry: ALTCK36A cnc lathe machining automatic numerical control lathe is aimed at high-speed rail locomotive body, axle, wheel and other parts.

2. Mold processing and manufacturing industry: the precision of parts is required to be high, and the surface precision mainly refers to the surface roughness. Cylindrical parts that require high cylindricity; conical parts that require high plane straightness, roundness, and inclination; rotating parts with special threads.ALTCK36A slant bed cnc lathe numerical control lathe can solve this problem well.

3. Defense industry: The ability of ALTCK36A slant bed cnc lathe to provide replacement parts and upgrade components on demand is especially useful in this industry. Therefore, it is suitable for components that require continuous innovation and safety.

4. Medical business field: ALTCK36A slant bed cnc lathe can be used for various medical safety materials. Since the process is suitable for one-off custom parts, it has many applications in the medical industry. The tight tolerances offered by the ALTCK36A cnc lathe machine are critical for high-performance machining of medical components.

ALTCK36A cnc lathe machine standard configuration:

1 CNC controller

2. Linear guide rail

3. Spindle unit speed 4000rpm

4.6 inch hollow hydraulic chuck

5.8 station hydraulic turret

6. Automatic lubrication system

7. Automatic cooling system

8. Work lights

ALTCK36A cnc lathe machine optional configuration:

1. Hydraulic 4-jaw chuck

2. Servo Turret/Power Turret

3. Chip conveyor

4. FANUC CNC controller

video:

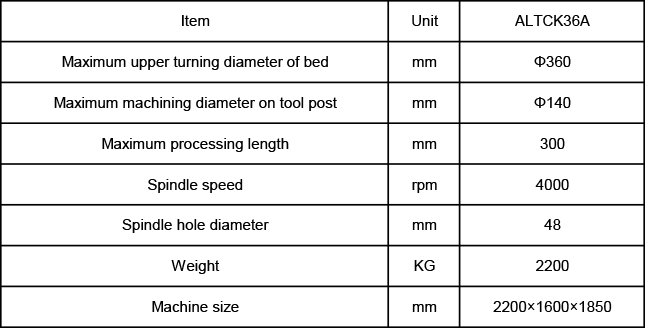

Product parameters: