PRODUCT

ALTCK46A slant bed cnc lathe

ALTCK46A Inclined Bed Linear Rail CNC Lathe ALTCK46A Inclined Bed Linear Rail CNC Lathe adopts a 30° integral inclined bed structure and is equipped with high-precision preload linear rolling guide rails from Taiwan, China. The machine tool has high position accuracy and smooth chip removal, suitable for high-speed and high-precision processing.

ALTCK46A slant bed cnc lathe is a high-speed, high-precision, high-reliability inclined bed machine tool. Adopting 30° overall inclined bed structure, equipped with high-precision preload Taiwan linear rolling guide, the machine tool has high position accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining. High-speed, high-precision, high-rigidity shell-type spindle unit, servo spindle motor, can reach higher spindle speed. The X/Z direction servo motor is directly connected to the lead screw through a large torque and low inertia elastic coupling. The lead screw support adopts a pre-stretched structure, which can eliminate the transmission backlash and pre-compensate the influence of thermal deformation on the accuracy of the machine tool during long-term operation. Ensure positioning accuracy and repeat positioning accuracy; adopt advanced centralized automatic lubrication device, timing and quantitative automatic intermittent lubrication, stable and reliable work.

Features of ALTCK46A cnc lathe machining:

1. Automated processing: ALTCK46A is a CNC lathe with a high degree of automation capabilities. It can automatically perform various machining operations including cutting, drilling, turning and threading according to pre-programmed instructions.

2. High precision and repeatability: This CNC lathe has a high-precision positioning and control system, which can achieve precise processing and ensure the dimensional and quality stability of parts. It is also highly repeatable, producing consistent parts.

3. Versatility: ALTCK46A CNC lathes usually have multi-axis control and can perform various complex machining operations. This makes it suitable for processing a variety of parts with different shapes and requirements.

4. Production efficiency: The automation features and high-speed processing capabilities of CNC lathes can improve production efficiency and reduce the need for manual intervention, thereby reducing production costs.

Uses of ALTCK46A cnc lathe machining:

1. Machinery manufacturing industry: CNC lathes are widely used in the machinery manufacturing industry and are used to process various metal and non-metal parts, including turning, milling, drilling, boring and threading of parts.

2. Aerospace industry: The aerospace field requires high-precision and high-quality parts, and CNC lathes can meet these requirements and are used to manufacture aircraft parts and spacecraft components.

3. Automobile manufacturing industry: Automobile manufacturing requires a large number of parts, and CNC lathes can be used to produce engine parts, braking system parts, steering system parts, etc.

4. Electronic industry: CNC lathes can be used to manufacture housings, radiators, connectors and other parts for electronic equipment.

5. Medical equipment manufacturing: Medical equipment requires highly precise components, and CNC lathes are used to manufacture components of various medical equipment, such as surgical tools and diagnostic equipment.

6. Energy industry: CNC lathes can be used to manufacture key components of energy equipment, such as generator parts, turbomachinery parts, and pump bodies.

ALTCK46A cnc lathe machine standard configuration:

1 CNC controller

2. Linear guide rail

3. Spindle unit speed 4000rpm

4.6 inch hollow hydraulic chuck

5.8 station hydraulic turret

6. Automatic lubrication system

7. Automatic cooling system

8. Work lights

ALTCK46A cnc lathe machine optional configuration:

1. Hydraulic 4-jaw chuck

2. Servo Turret/Power Turret

3. Chip conveyor

4. FANUC CNC controller

video:

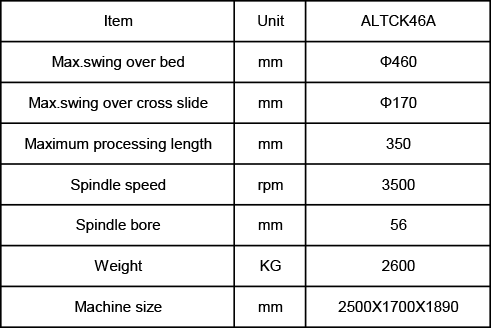

Product parameters: