PRODUCT

ALTCK50A cnc lathe machine

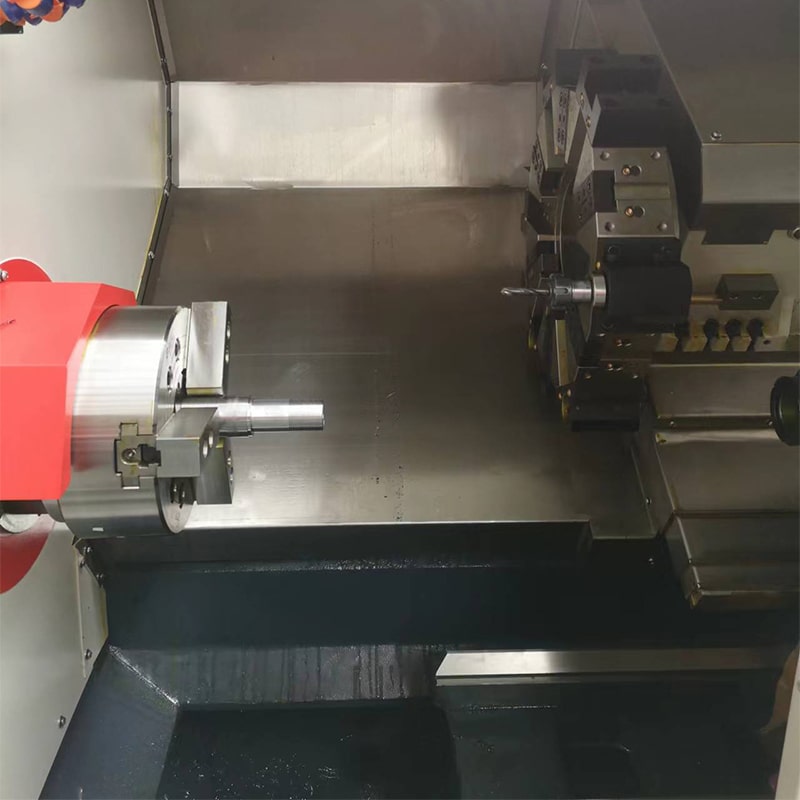

TCK50A slanted bed line rail CNC lathe adopts 30° integral slanted bed structure, equipped with high-precision preload Chinese linear rolling guide rail, the machine tool has high position accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining

TCK50A slanted bed adopts a high-precision spindle bearing group and a spindle that has been precision assembled and dynamically balanced to ensure high precision, low noise and strong rigidity. Using the turret mode, the tool change speed is fast and the positioning accuracy is high. TCK50A slanted bed The servo motor is directly connected to the lead screw through a high-torque low-inertia elastic coupling to ensure positioning accuracy and repeat positioning accuracy. Adopting advanced centralized automatic lubricating device, regular and quantitative automatic intermittent lubrication, stable and reliable work.

Features of ALTCK50A cnc lathe machining:

1. Automated control: The metal CNC lathe ALTCK50A uses a computer control system, which can accurately control the position, speed and cutting depth of the tool to achieve high-precision and highly repeatable processing.

2. Versatility: Metal CNC lathe ALTCK50A usually has multi-axis control and can perform a variety of different cutting and processing operations, such as turning, boring, tapping, etc.

3. High precision: Due to computer control, the metal CNC lathe ALTCK50A is able to achieve very high machining precision and is suitable for industries that require high-precision parts.

4. Automated production: The small CNC lathe ALTCK50A can perform long-term continuous processing, reducing manual intervention and improving production efficiency.

5. Flexibility: By changing the processing program, the small CNC lathe ALTCK50A can be used to process workpieces of different shapes and sizes, providing production flexibility.

Uses of ALTCK50A cnc lathe machining:

1. Machinery manufacturing industry: The metal CNC lathe ALTCK50A is widely used in manufacturing various mechanical parts, bearings, gears, threads, etc.

2. Aerospace industry: The metal CNC lathe ALTCK50A is used to manufacture high-precision parts such as aircraft parts and spacecraft components.

3. Automobile manufacturing industry: The metal CNC lathe ALTCK50A is used to produce automobile engines, transmission systems, brake parts and other automobile parts.

4. Medical equipment manufacturing industry: used to manufacture parts for medical equipment, such as artificial joints, orthopedic implants, etc.

5. Electronic manufacturing industry: The small CNC lathe ALTCK50A is used in the housings, connectors, circuit boards, etc. of electronic equipment.

6. Mold manufacturing industry: Small CNC lathe ALTCK50A is used to manufacture plastic molds, die-casting molds, etc.

ALTCK50A cnc lathe machine standard configuration:

1 CNC controller

2. Linear guide rail

3. Spindle unit speed 4000rpm

4.6 inch hollow hydraulic chuck

5.8 station hydraulic turret

6. Automatic lubrication system

7. Automatic cooling system

8. Work lights

ALTCK50A cnc lathe machine optional configuration:

1. Hydraulic 4-jaw chuck

2. Servo Turret/Power Turret

3. Chip conveyor

4. FANUC CNC controller

video:

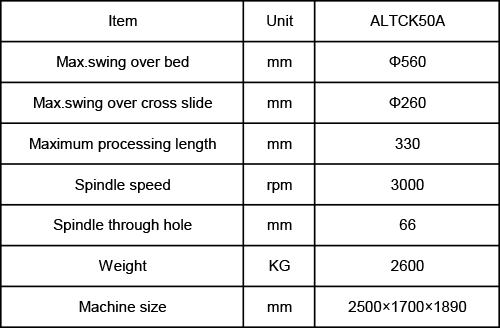

Product parameters: