PRODUCT

ALTCK66A slant bed cnc lathe

ALTCK66A Inclined Bed Linear Rail CNC Lathe ALTCK66A Inclined Bed Linear Rail CNC Lathe adopts a 30° integral inclined bed structure and is equipped with high-precision preload linear rolling guide rails from Taiwan, China. The machine tool has high position accuracy and smooth chip removal, suitable for high-speed and high-precision processing.

ALTCK66A slant bed cnc lathe is a high-speed, high-precision, high-reliability inclined bed machine tool. Adopting 30° overall inclined bed structure, equipped with high-precision preload Taiwan linear rolling guide, the machine tool has high position accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining. High-speed, high-precision, high-rigidity shell-type spindle unit, servo spindle motor, can reach higher spindle speed. The X/Z direction servo motor is directly connected to the lead screw through a large torque and low inertia elastic coupling.

Features of ALTCK66A cnc lathe machining:

1. High-precision processing: The metal ALTCK66A CNC lathe adopts advanced CNC technology, which can achieve high-precision processing and ensure that the size and quality of the workpiece meet the requirements.

2. Versatility: This CNC lathe has a variety of processing functions, including turning, drilling, milling, etc., and can adapt to different types of workpiece processing needs.

3. Efficient production: The metal ALTCK66A CNC lathe has a high degree of automation and can operate continuously, which improves production efficiency and reduces labor costs.

4. Stability and durability: It has a stable structure, careful design and material selection, and has excellent durability and is suitable for long-term operation.

5. User-friendly: The inclined bed CNC lathe ALTCK66A has a friendly operation interface, which is easy to set up and control, reducing operator training time.

Uses of ALTCK66A cnc lathe machining:

1. Manufacturing industry: The horizontal ALTCK66A CNC lathe is widely used in the manufacturing industry for processing various metal and plastic parts, including automotive parts, aviation parts, engineering machinery parts, etc.

2. Aerospace: In the aerospace industry, metal ALTCK66A CNC lathes are used to manufacture high-precision workpieces such as aircraft parts, spacecraft parts, and missiles.

3. Medical equipment: Medical equipment manufacturing requires high-precision and high-quality parts. The inclined bed ALTCK66A CNC lathe can be used to manufacture parts for medical equipment such as X-ray machines, surgical tools, artificial joints, etc.

4. Energy industry: In the energy industry, metal ALTCK66A CNC lathes are used to process oil and gas extraction equipment, generator set parts, and nuclear power plant parts.

5. Mold manufacturing: Mold manufacturing is another important application area, and the ALTCK66A CNC lathe can be used to manufacture various types of molds, including plastic injection molds and die-casting molds.

ALTCK66A cnc lathe machine standard configuration:

1 CNC controller

2. Linear guide rail

3. Spindle unit speed 4000rpm

4.6 inch hollow hydraulic chuck

5.8 station hydraulic turret

6. Automatic lubrication system

7. Automatic cooling system

8. Work lights

ALTCK66A cnc lathe machine optional configuration:

1. Hydraulic 4-jaw chuck

2. Servo Turret/Power Turret

3. Chip conveyor

4. FANUC CNC controller

video:

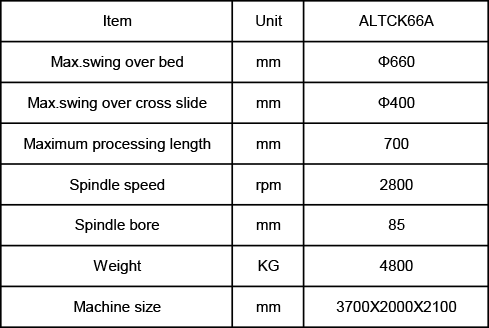

Product parameters: