PRODUCT

ALCK6150X1000 cnc lathe machine

ALCK6150 flat bed cnc lathe is a fully automatic lathe with high precision and high efficiency. The lathe can be equipped with multiple station turrets or power turrets. The CNC lathe CK6150 has a wide range of processing performance and is suitable for turning of disc and shaft parts. High-precision machining of complex processes such as prisms, multi-end faces, and multi-angles, and has played a good economic role in the mass production of complex parts.

ALCK6150 CNC lathe is easy to operate, especially suitable for processing complex parts or high-precision mass parts, and it is also the choice of CNC teaching. The electric four-station tool post is positioned by a precision toothed disc, with high repeat positioning accuracy.

ALCK6150 flat bed cnc lathe features:

1. CNC system: The horizontal CNC lathe ALCK6150X1000 is equipped with a CNC system, which usually uses advanced controllers such as Siemens, Fanuc, or Mitsubishi.

2. Workbench size: Indicates the maximum workpiece size that the lathe can process. In the horizontal CNC lathe ALCK6150X1000, the workbench diameter is 6150mm and the length is 1000mm.

3. Spindle: The horizontal CNC lathe ALCK6150X1000 is equipped with a high-performance spindle, which can provide sufficient power and speed to meet different processing needs.

4. Tool turret: The automatic turret system for tool switching can improve production efficiency.

5. Feeding system: High-precision feeding system is used to control the movement of tools during processing to achieve precise processing.

6. Tools and fixtures: Equipped with tools and fixtures suitable for different processes to meet various processing needs.

7. Automatic lubrication system: In order to maintain the good operating condition of machine tools, automatic lubrication systems are usually equipped.

8. Safety system: Including emergency stop buttons, safety shields and other safety equipment to ensure the safety of operators.

ALCK6150 flat bed cnc lathe application:

1. Railway locomotive manufacturing industry: ALCK6150 horizontal cnc lathe is widely used in the processing and utilization of high-speed rail locomotive car bodies, axles, wheels and other parts, which are difficult to process and require high precision.

2. Steel processing field: ALCK6150 automatic cnc lathe can be used to process bearings, bushings, journals and other parts to improve production efficiency and product quality. Its excellent performance and reliability make it the key to the processing field.

3. In the field of construction machinery: ALCK6150 automatic cnc lathe is widely used in the processing and utilization of workpieces including shafts, gears, bushes, flywheels, cams, molds, spirals and other workpieces, which are difficult to process and require high precision. CNC machine tools have unique advantages of high precision and high efficiency, which can better solve these problems.

4. Power generation equipment field: ALCK6150 automatic cnc lathe is widely used in processing key components of wind turbines such as horizontal main shaft, wind wheel, gearbox, generator, etc.

ALCK6150 flat bed cnc lathe standard configuration:

1. CNC system

2. Four-station electric knife holder

3. Ordinary three-jaw chuck

4. Ordinary tailstock

5. Frequency conversion main motor

6. Cooling system, automatic lubrication

ALCK6150 cnc lathe machining optional configuration:

1. Same server main motor

2. Pneumatic or hydraulic chuck

3. Pneumatic hydraulic collet

4. Six or eight station tool post

video:

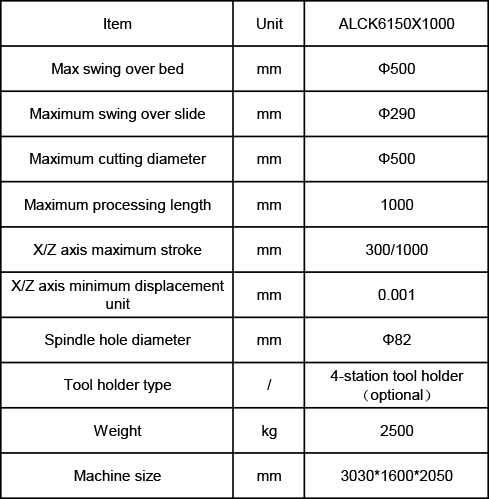

Product parameters: