PRODUCT

ALCK6130 cnc lathe machine

ALCK6130 CNC lathe is a high-precision, high-performance small-scale precision machine tool, which is used for high-volume and high-efficiency processing of various high-precision and complex small-scale rotary parts in the instrumentation, electronic medical equipment and aviation industries. The spindle adopts precision angular contact bearings, which can The optimal combination of high precision and high speed is obtained, and the service life is long. The X and Z axes adopt high-precision ball screws, which have good dynamic performance and high positioning precision. The center screw is used to make the structure more reasonable and improve the processing precision.

The guide rail of this machine tool is made of high wear-resistant cast iron and has been subjected to super-audio frequency quenching treatment and artificial vibration aging treatment, which can ensure the geometric accuracy of the machine tool for a long time and stably. The vertical and horizontal carriages are driven by high-precision ball screws, with good dynamic performance and high displacement precision. All the sliding surfaces of the machine tool are lubricated by centralized dripping. This machine tool is widely used in the processing and manufacturing of electrical appliances, hardware tools, valves, gas pipe fittings and other complex parts. It is an ideal equipment for the hardware machining industry.

CNC lathe ALCK6130 is a CNC machine tool used for metal processing. Its features include:

1. High precision: CNC lathe ALCK6130 adopts a digital control system, which can achieve precision machining and improve machining accuracy and stability.

2. Automation: CNC lathe ALCK6130 can automatically perform processing operations through preset programs, saving labor costs and improving production efficiency.

3. Versatility: CNC lathe ALCK6130 can process various complex shapes, such as turning, boring, tapping and other process operations, and has strong versatility.

4. Energy saving and environmental protection: Compared with traditional lathes, CNC lathe ALCK6130 has a higher energy efficiency ratio, which can reduce energy consumption and environmental pollution.

ALCK6130 horizontal cnc lathe machine application:

1. Aerospace industry: ALCK6130 cnc metal lathe is widely used in the manufacture of aircraft engine parts, aircraft structural parts, aerospace instruments and spacecraft components, etc. The high-precision requirements of the aerospace industry for parts make this CNC lathe an essential processing equipment.

2. Shipbuilding and nautical industry: ALCK6130 cnc metal lathe is used in the manufacture of large crankshafts in ships, marine machinery and instrument manufacturing, etc. ALCK6130 cnc metal lathe provides efficient, convenient and precise production capability.

3. Arms manufacturing industry: ALCK6130 cnc turning center is used in the development and design of multi-station processing of complex parts, mainly used for grinding the inner holes and end faces of discs, shafts (or similar parts), suitable for parts Mass production has the unique advantages of high precision and high efficiency.

4.Power generation equipment manufacturing industry: ALCK6130 cnc turning center is widely used in processing key components of wind turbines, such as horizontal spindles, wind wheels, gearboxes, generators, etc. It is difficult to process and requires high precision. This CNC machine tool can better solve the problem Solved complex, precise, small batch, multi-variety parts processing problems。

The standard configuration of ALCK6130 flat bed cnc lathe:

1.GSK CNC system;

2.Four-station electric knife post;

3.Manual chuck.

4.Hydraulic chuck;

5.Six-station electric knife post;

6.Overall lathe body structure;

7.Domestic frequency converter;

8.Ordinary three-phase asynchronous motor;

9.Pneumatic spring clamp clamping device;

10.Four sets of 16*16 square knife holders;

11.Fully enclosed casing, a set of cooling device and lighting device.

Optional configuration of ALCK6130 horizontal cnc lathe:

1.6/8-station rotary tool post

2.Pneumatic tailstock;

3.Taiwan's precision and flexible top;

4.Various non-standard collets;

5.Puller;

6.Hollow, solid hydraulic three-jaw chuck or spring chuck quick tightening device;

video:

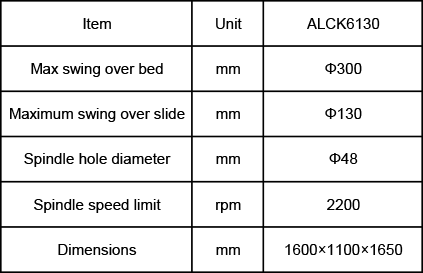

Product parameters: