PRODUCT

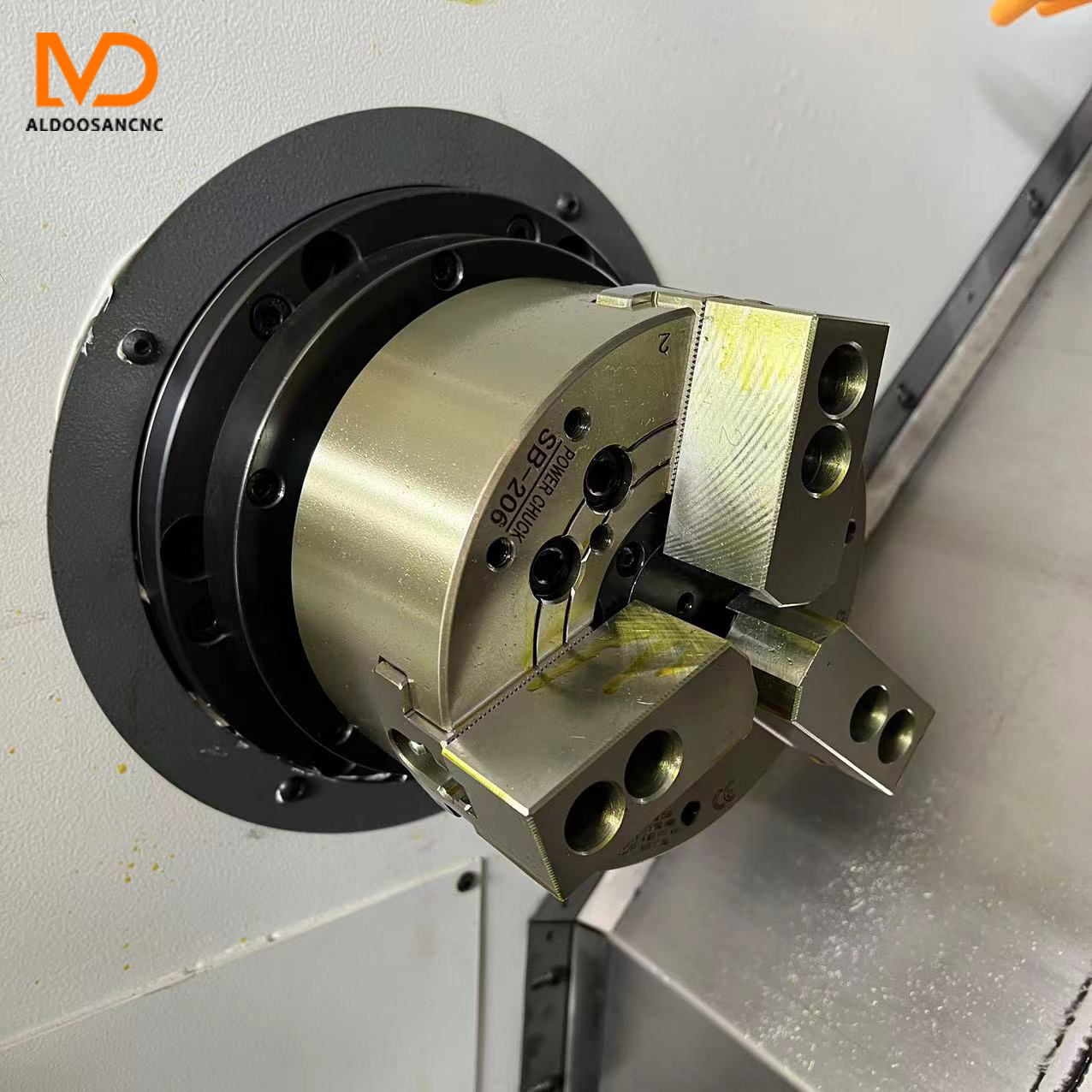

ALFCK40 Slant Bed CNC Lathe

The ALFCK40 Slant Bed CNC Lathe is a high-performance precision turning machine featuring a 45-degree slant bed design for superior rigidity, smooth chip removal, and high machining efficiency. It is widely used in industries such as automotive, aerospace, electronics, medical equipment, and general metalworking for producing small to medium-sized high-precision metal parts. This lathe is an ideal choice for manufacturers seeking stability, accuracy, and efficiency in mass production.

FCK40 Slant Bed CNC Lathe – Product Introduction

The FCK40 Slant Bed CNC Lathe is a precision-engineered turning machine designed for high-efficiency and high-accuracy metal processing. Its 45-degree slant bed structure improves chip removal and provides excellent rigidity, allowing for stable performance during continuous or heavy-duty machining. Compact in size but powerful in capability, this model is ideal for manufacturers seeking reliable solutions for small to medium-sized part production.

Main Features:

1. 45° slant bed design enhances chip evacuation and machine rigidity High-speed

2. spindle with excellent rotation accuracy and thermal stability

3. Precision linear guideways reduce friction and improve movement accuracy

4. User-friendly CNC control system for intelligent and automated machining

5. Compact structure suitable for limited floor space while maintaining high productivity

6. Capable of processing various materials such as carbon steel, stainless steel, aluminum, copper, and alloys

7. High repeatability and low maintenance costs, ensuring long-term performance

Application Industries:

The FCK40 is widely used in industries requiring precision and efficiency:

l Automotive: Machining of small engine components, gear blanks, shafts, and fittings

l Aerospace: Production of lightweight, high-strength alloy parts

l Medical Equipment: Turning of complex, high-precision components like implants and surgical tools

l Electronics: Processing of connectors, housings, and metal pins

l General Manufacturing: Ideal for custom parts, tooling components, and batch production of metal parts

With its robust design and advanced technology, the FCK40 is the perfect solution for workshops and factories aiming to improve machining quality and productivity.

Product Parameters: