PRODUCT

ALFCK50 Slant Bed CNC Lathe

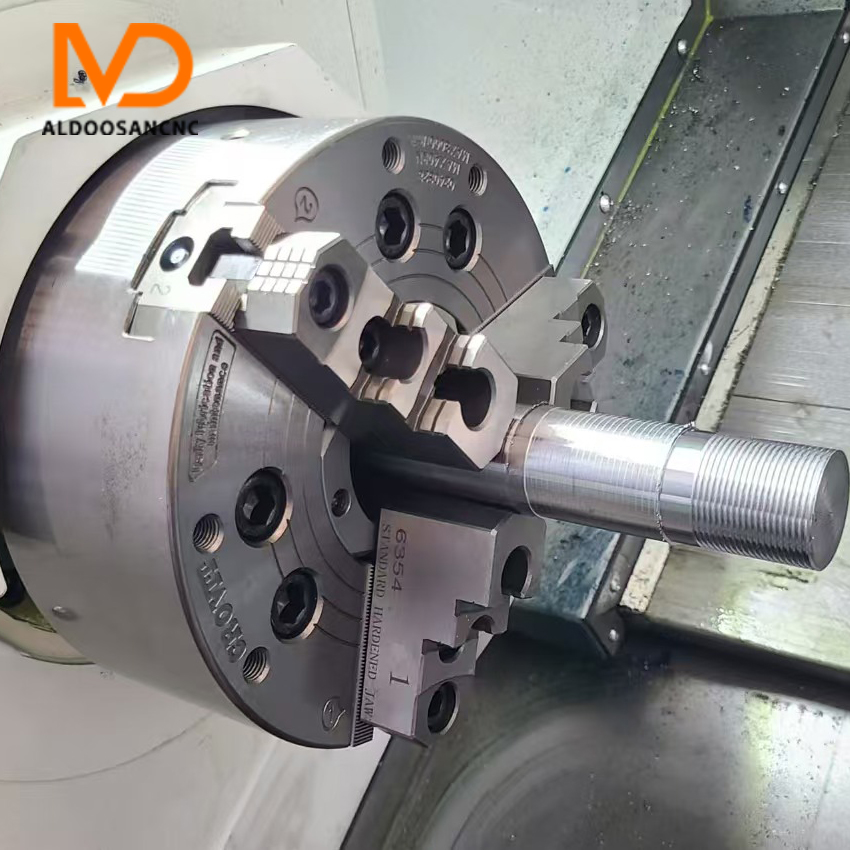

The ALFCK50 Slant Bed CNC Lathe is a high-performance machine featuring a slant bed design that offers excellent rigidity and efficient chip removal. It is suitable for high-efficiency, high-precision metal part machining. This lathe is widely used in manufacturing environments that demand accuracy and stability, making it an ideal solution for automated and mass production needs in modern industrial applications.

ALFCK50 Slant Bed CNC Lathe – Detailed Introduction

The ALFCK50 is a slant bed CNC lathe that combines high rigidity, high precision, and high efficiency. The machine body adopts an integrated casting structure with a 45-degree inclined bed, ensuring excellent chip evacuation and machining stability. It is equipped with a high-performance servo spindle and roller linear guideways, enhancing the machine’s responsiveness and service life. The fully enclosed protective cover and automatic lubrication system ensure safe and clean machining while reducing maintenance costs.

Main Features

l Slant bed structure with strong rigidity and smooth chip removal

l High-precision roller linear guideways for improved machining stability

l Servo-driven spindle with fast response and high torque

l Automatic lubrication system for extended equipment life

l Compatible with hydraulic chuck or collet chuck for flexible clamping

l Optional automatic bar feeder for fully automated production

Application Industries

1. Aerospace Industry

Used for machining complex alloy components requiring high precision, such as connectors, fasteners, and small shafts.

2. Automotive Manufacturing

Ideal for mass production of engine parts, steering system components, drive shafts, and gears.

3. Medical Equipment

Suitable for producing surgical instruments, orthopedic components, and precision joints with strict requirements on accuracy and surface finish.

4. Electronics & Communication

Used to manufacture precision connectors, housings, and small shaft components for electronic devices.

5. Instrumentation

Capable of machining precision shafts, housings, and connection parts used in measurement instruments.

6. Hardware Tools

Perfect for producing high-strength and consistent tool components like tool holders, couplings, and threaded parts in bulk.