PRODUCT

ALCK6180×2000 cnc lathe machine

ALCK6180×2000 cnc lathe machine is an economical and practical CNC lathe with mature structure, stable performance, high quality, easy programming and simple operation. It is suitable for the inner and outer surfaces, conical surfaces, arc surfaces, Drilling, reaming and reaming of various threads and even holes are especially suitable for the sequential processing of multiple varieties and small and medium batches of parts.

ALCK6180×2000 cnc lathe machine is suitable for processing all kinds of steel, cast iron and non-ferrous metal large and medium-sized parts.ALCK6180×2000 CNC machine tool has high power and good rigidity. It is especially suitable for powerful cutting, cutting inner circle, outer circle, end face, and metric and inch parts of various workpieces. Thread, etc., and can undertake drilling and boring processes.

The automatic CNC lathe ALCK6180X2000 is a high-precision and high-efficiency CNC equipment with the following characteristics:

1. High-precision processing: The automatic CNC lathe ALCK6180X2000 adopts an advanced CNC system, which can achieve high-precision processing and meet processing tasks that require high dimensional accuracy and surface quality of workpieces.

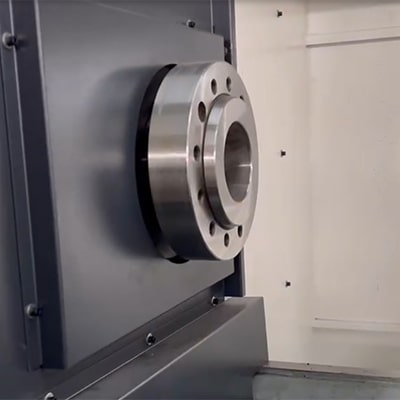

2. High-power spindle: The automatic CNC lathe ALCK6180X2000 has strong spindle power, can adapt to various processing requirements, and can achieve high-speed processing and heavy cutting.

3. Multi-station tool magazine: The horizontal CNC lathe ALCK6180X2000 has a multi-station tool magazine, which can automatically replace tools during the processing process to improve production efficiency and processing accuracy.

4. Strong stability: The horizontal CNC lathe ALCK6180X2000 adopts high-quality materials and precision processing technology, has high stability, can operate stably for a long time, and effectively maintains processing accuracy.

5. Wide application: CNC lathe CK6180X2000 is widely used in aerospace, automotive, electronics, instrumentation and other industries. It can process various materials, including metal, plastic, carbide, etc., and can be used to manufacture shafts, gears, threads, cams, sleeves and other parts.

ALCK6180×2000 Horizontal CNC Lathe Application:

1. Aerospace industry: Horizontal CNC lathe ALCK6180X2000 is suitable for manufacturing aircraft engine parts, aircraft fuselage parts and aerospace devices, ensuring high precision and reliability.

2. Automobile manufacturing: In automobile manufacturing, flat bed CNC lathe ALCK6180X2000 can be used to process key components such as engine parts, braking system and transmission system.

3. Energy field: In the energy industry, the flat bed CNC lathe ALCK6180X2000 can be used to process turbine parts, generator parts and nuclear energy equipment.

4. Railway and transportation equipment: The flat bed CNC lathe ALCK6180X2000 can be used to manufacture parts for train wheels and rails, railway transportation equipment and other large transportation equipment.

5. Heavy industry and machinery manufacturing: In various heavy industry applications, such as steel manufacturing, shipbuilding and construction machinery manufacturing, the metal ALCK6180X2000 CNC lathe has the ability to process large workpieces.

6. Medical equipment manufacturing: In medical equipment manufacturing, it can be used to manufacture high-precision medical equipment components, such as medical imaging equipment and surgical tools.

ALCK6180×2000 turning cnc lathe standard configuration:

1.CNC system,

2.Integral landing bed,

3.Heavy-duty rail width 600mm,

4.11KW ordinary main motor,

5.11KW domestic frequency converter,

6.CK6180 (Φ630 manual four-jaw chuck or Φ400 three-jaw chuck),

7.manual tailstock,

8.Four-station electric tool post,

9.automatic lubrication system,

10.electric cooling system,

11.Lighting system,

12.semi-enclosed shield,

13.Delixi electrical control components,

14.A full set of technical information,

15.Random standard accessories and tools.

ALCK6180×2000 turning cnc lathe optional configuration:

1.Square head gear box three-speed variable frequency segmental variable speed CNC lathe

2.Optional manual four-speed internal stepless transmission,

3.Optional spindle servo motor (11KW).

video:

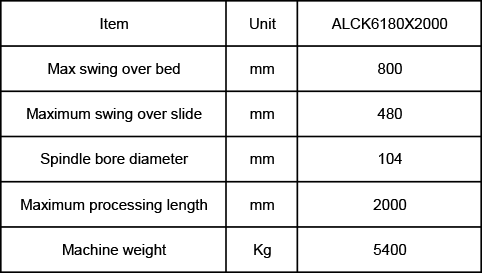

Product parameters: